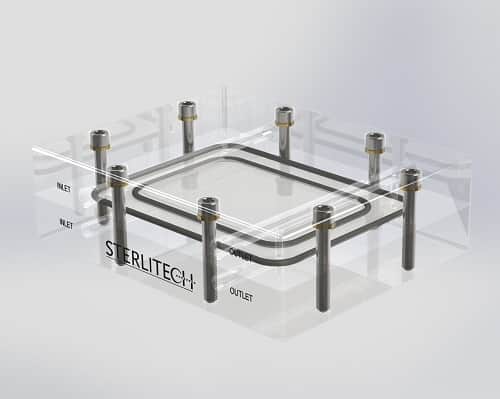

Sterlitech is pleased to offer a “plug and play” DCMD test cell. The first commercially available bench-scale cross/tangential flow test cell, that mimics conditions representative of large-scale DCMD systems with minimal amounts of membrane or product. This offers researchers fast and accurate performance data to easily evaluate the performance of membranes and/or the membrane separation processes.

“Adding the DCMD test cell to the Membrane and Process Development product line complements this line of product by offering researchers a bench-scale cross/tangential flow test cell for evaluating Temperature-Driven membrane separation processes,”

- said Sepideh Jankhah, Product Manager at Sterlitech Corporation.

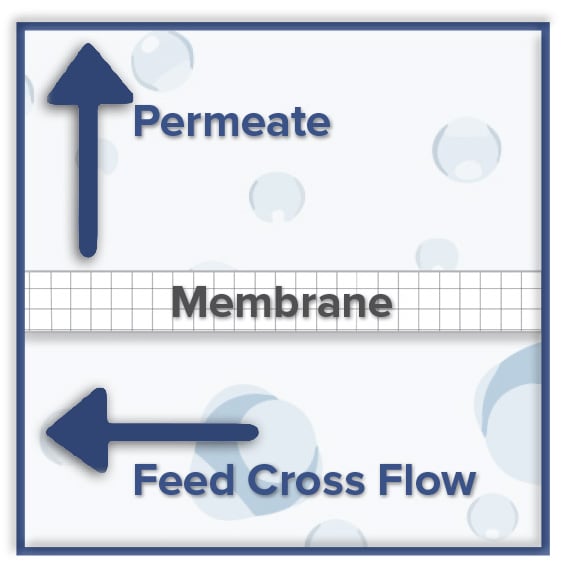

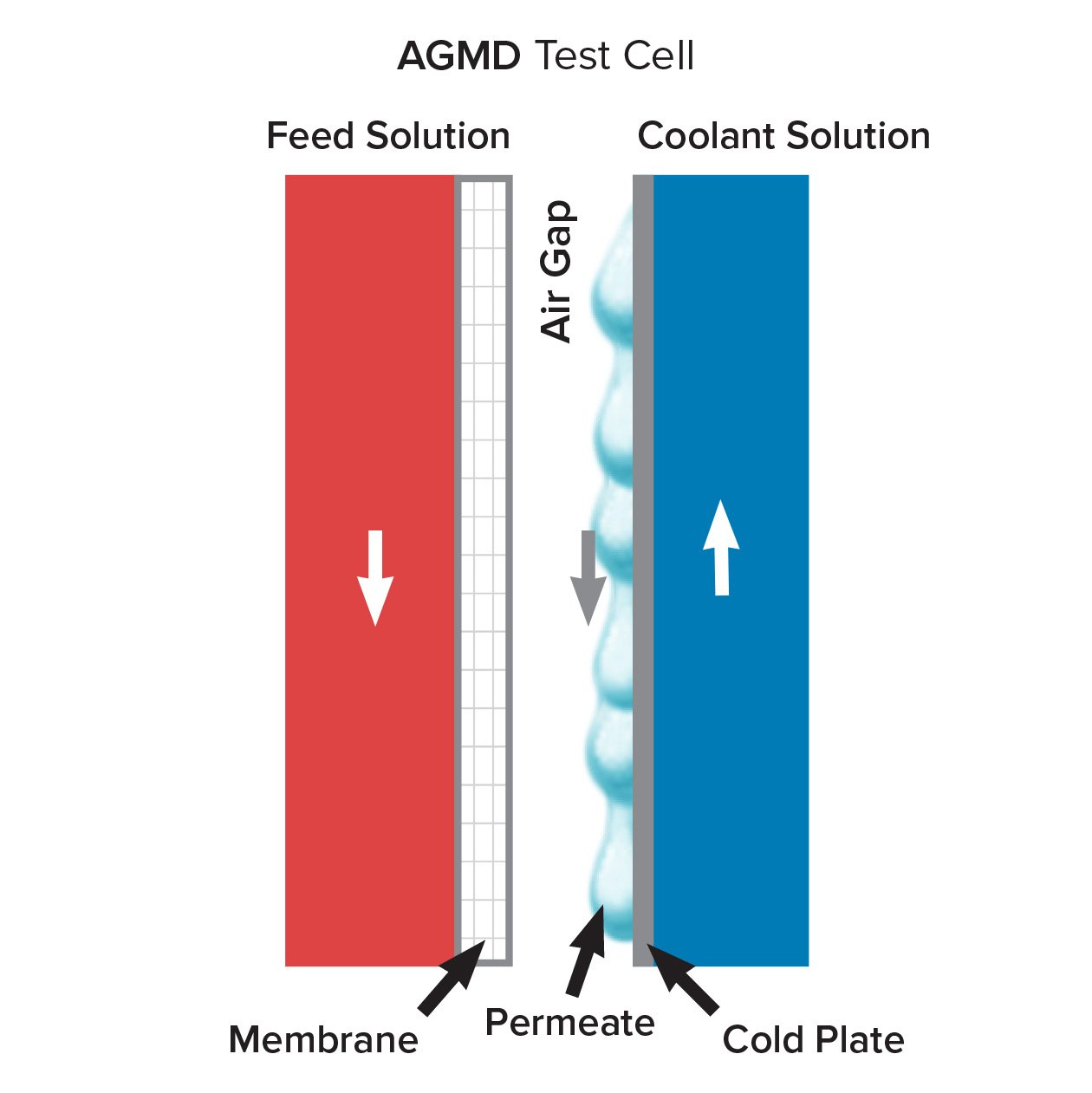

How it works: the liquid to be treated is circulated in direct contact with the feed side of the membrane in the Sterlitech’s DCMD cell. A cold liquid solution is circulated in direct contact with the permeate side of the membrane.

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)