In order to provide a safe work environment, better control of vapor wastes needs to be implemented. EZ waste technology has become readily available to improve the containment of volatile liquids and prevent vapors from escaping into laboratory air. Learn about how to prevent the dangers of hazardous waste and the technology behind the closed waste system with an activated carbon filter, such as the EZ waste system. Download EZwaste whitepaper for more detail and additional instruction.

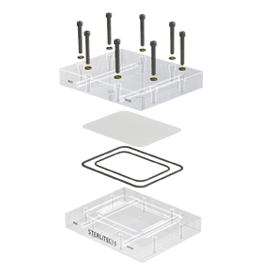

Explore EZ Waste Solvent Waste System product line at Sterlitech

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)