Continuing demand for low energy solutions to separation challenges have fueled Sterlitech’s latest product release: an Air Gap Membrane Distillation Cell. The first commercially available bench-scale tangential flow test cell of its kind, it mimics conditions representative of large-scale systems with minimal use of membrane or product. The AGMD cell offers researchers fast and accurate performance data to easily evaluate the performance of membranes and/or the efficiency of a given process with respect to their application.

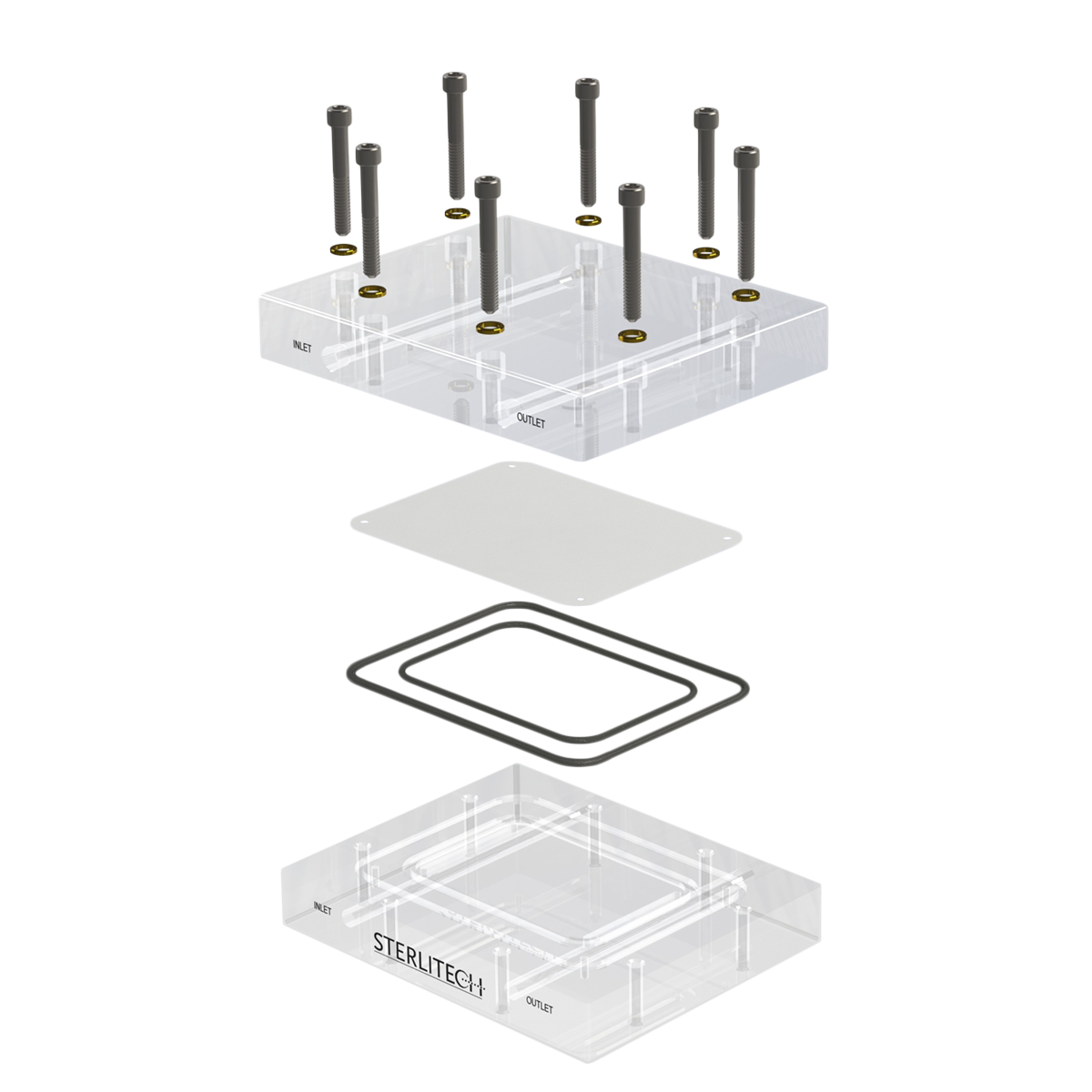

How it works: liquid to be treated is circulated in direct contact with the feed side of the membrane in the AGMD cell. A cold liquid solution is circulated in direct contact with a cooling plate on the permeate side of the membrane. Both the feed and the cooling solutions are circulated tangentially while using pumps at low or no hydrostatic pressures. An air gap is created between the permeate side of the membrane and the cooling plate where permeate is condensed and collected through a permeate collection tube at the bottom of the gap.

Membrane Distillation (MD) is widely applied in desalination, concentration in food processing, acid manufacturing, removing organic and heavy metals, and in treating radioactive waste. The MD process offers advantages such as:

- Low operating temperatures

- Low hydrostatic pressures

- Less susceptibility to fouling

- Ability to use renewable energy or waste heat

This all translates into lower energy requirements, compared to high pressure or high temperature processes.

To obtain more information about Sterlitech’s AGMD cellor MD membranes, contact a Membrane and Process Development expert at Sterlitech at 1-877-544-4420 or [email protected].

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)