SterliTECH Tip: Membrane Substitution

Membrane filters can be defined as a microporous film that serves as a barrier, allowing the flow of fluids or gasses while preventing the passage of particles and microorganisms. These filters have specific ratings for their pore sizes which is vital to keep the microorganisms or particles which are bigger than the size of their pores through the process of surface capture. Membrane filtration utilizes pressure in order to force water or any other kind of carrier (fluid or gas) through a porous or semi-permeable membrane. This process separates the particulate matter that's suspended from the soluble and carrier components.

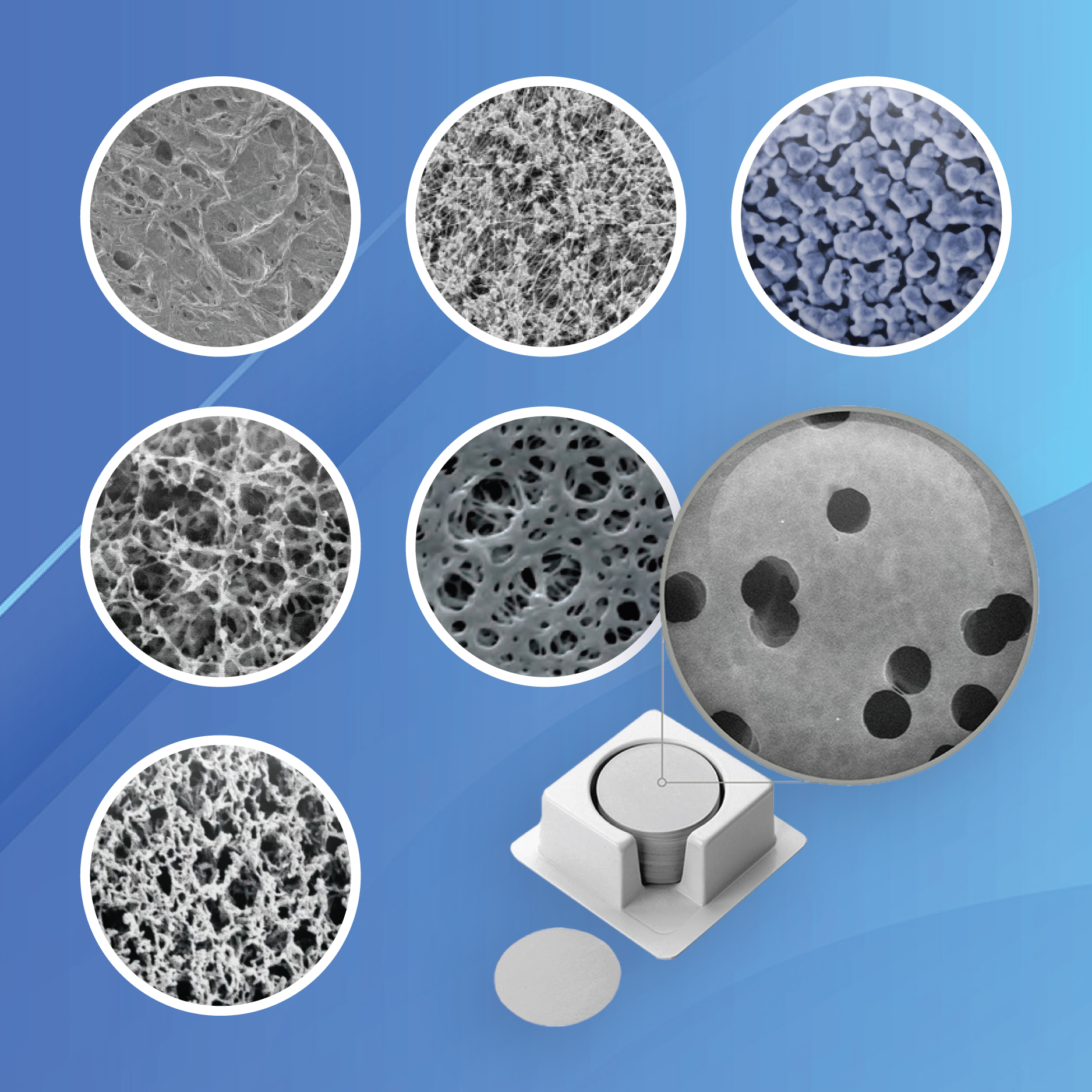

Membrane selection is critical to successfully achieving desired filtration goals, and should be influenced by the nature of the sample to filter, membrane chemical compatibility, maximum pore size requirement and the filtration goals itself. A variety of membrane materials and structures are available on the market, including natural polymers and their derivatives (mixed cellulose esters, cellulose triacetate), tailored synthetic polymers (polysulfone, polyamides, etc.), ceramic, glass fiber and metallic membranes.

Sterlitech offers the largest selection of unique membrane filters for routine and novel applications. You can narrow down the choices by starting with our Membrane Selection Guide. Keep in mind there may be more than one membrane compatible with your application, which can be helpful if a substitution is necessary.

You can also refer to the quick reference table below.

|

Filtration Requirement |

Compatible Filter Membrane |

|---|---|

|

Hydrophilic Syringe Filter |

|

|

Hydrophobic Syringe Filter |

|

|

Compatible with aqueous samples only |

|

|

Compatible with organic and aqueous samples |

|

|

Compatible with gaseous samples |

|

|

Low protein binding |

|

|

High Protein binding |

|

|

Nonspecific binding |

|

|

Excellent flow rates |

|

|

High throughput loading |

|

|

Infrared spectroscopy / Light microscopy |

Silver, PCTG, Silicon, Aluminum Oxide |

|

Gas venting |

|

|

Air Particle filtration |

|

|

High thermal resistance (>121℃) |

CA, GF, Glass Nylon, MCE, PES, PTFE or PVDF, Ceramic (350℃), Silver (427℃) |

Still have questions? Ask an Expert to learn more about how our membranes can solve your filtration challenges.

- Most Viewed Blog Articles (5)

- Company News (284)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)