What is membrane preconditioning and why is it recommended to precondition new flat sheet or spiral wound membranes prior to use?

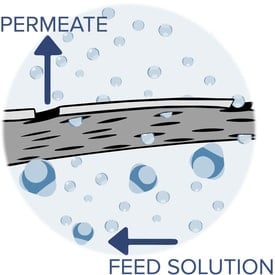

Membrane preconditioning is a filtration step using deionized water as feed solution and is typically performed at a pressure equal to or higher than the anticipated testing pressure. During this process membrane pores are wetted and the membrane structure may go through compaction or swelling, affecting both the permeate flux and the rejection values. Preconditioning will help ensure that the membrane performs according to the specs provided by the manufacturer.

Are FO membranes preconditioned the same way?

Aquaporin Inside™ flat sheet FO membranes should be soaked in DI water for a minimum of 30 min. Once wet, the membrane should not be allowed to dry.

How about preconditioning Hollow Fiber FO modules?

Aquaporin's Hollow Fiber FO module is delivered wet and no pre-conditioning is required. However, pre-filtration of the feed solution being filtered on the lumen side is required. Un-removed particles may damage the fibers and result in a decrease in performance.

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)