Frequently Asked Questions

Learn more on what Sterlitech Corporation has to offer. Find answers to your questions about our filtration products here!

Membrane/Process Development FAQ

Are your PP spacers FDA compliant?

Yes, our Bi-Planar Feed Spacer Mesh is extruded from FDA compliant polypropylene

Are your PP spacers FDA compliant?

Yes, our Bi-Planar Feed Spacer Mesh is extruded from FDA compliant polypropylene.

Do you need a Chemical Compatibility Chart?

We have a Chemical Compatibility Chart that you can use for reference.

How do I install/remove permeate fittings or other plastic NPT fittings?

Sterlitech recommends to install all plastic fittings by hand using PTFE tape. If a plastic NPT or compression fitting starts to leak during operational testing, tighten the fitting carefully until the leaking stops. Excessive tightening may break the fitting or damage other components.

If the fittings is broken and stuck in the cell top, use a spiral flute extractor bit or similar tool to release the portion of the fitting in the cell top. If the cell top becomes cracked from removal efforts, a replacement can be purchased.

Why is the flat sheet membrane I'm using measuring a flux value less than the published flux value?

Flow characteristics for a spiral element and flat sheet membrane are significantly different and are really only comparable on a qualitative basis. Variability in the membrane manufacturing process, differences in water composition, test procedures, and test equipment, used in a factory, laboratory, or elsewhere, will impact water flux results.

What is the application of permeate carriers?

Permeate carriers, also known as “permeate water carriers” are aids that are installed between two layers of the flat sheet membranes in a spiral wound element. The main application of this collection layer is to prevent the membrane layers from closing in on each other under high-pressure operations and also facilitate the collection of permeate water.

What is the recommended flow rate for the CF cells?

lease refer to the following diagram to examine recommended feed flow rates for the crossflow cell you are working with.

What is the recommended replacement frequency for the Hydracell pump oil?

Hydracell pump oil needs to be changed after the first 100 hours of operation. Then, pump oil should be changed according to the guidelines described in the pump user manual. For more information on the pump please see user manual.

What is the maximum tolerance for feed water viscosity and particle size for the Hydracell pump (high pressure feed pump)?

The maximum feed water and the maximum solids size for the Hydracell pump are 150 cP and 200 µm, accordingly.

What is the thickness of feed spacers (17, 31, 47, and 65 mil diamond spacers)?

The “mil” measurement represents 1/1000th of an inch. Therefore, the thicknesses are 0.017, 0.031, 0.047, 0.065 inches (17, 31, 47, and 65 mil, accordingly).

What is the application of feed spacer?

Feed spacers are used to mimic the hydrodynamic conditions of large-scale membrane modules by changing the flow regime and creating turbulence inside the feed channel of our membrane test cells.

For more information on feed spacers incorporated into our test cells, please visit here.

My pressure regulator valve is clogged and it fails to adjust the flow as expected.

Product: Flow/pressure regulator valves: 1149421/ 1149428/1149427

Q: My pressure regulator valve is clogged and it fails to adjust the flow as expected.

A: The valve should be disassembled and cleaned with pressurized air.

What is the recommended range of cross flow velocity in commercially available spiral wound elements?

Cross flow velocity limits for commercially available spiral wound elements depend on the element construction limits, recommended maximum pressure drop in an element, and feed characteristics. The recommended values could be obtained form the manufacturers. Please contact Sterlitech for more information.

What are the differences between the crossflow test cells and the Sterlitech HP4750 stirred cell?

Q. What are the differences between the crossflow test cells and the Sterlitech HP4750 stirred cell?

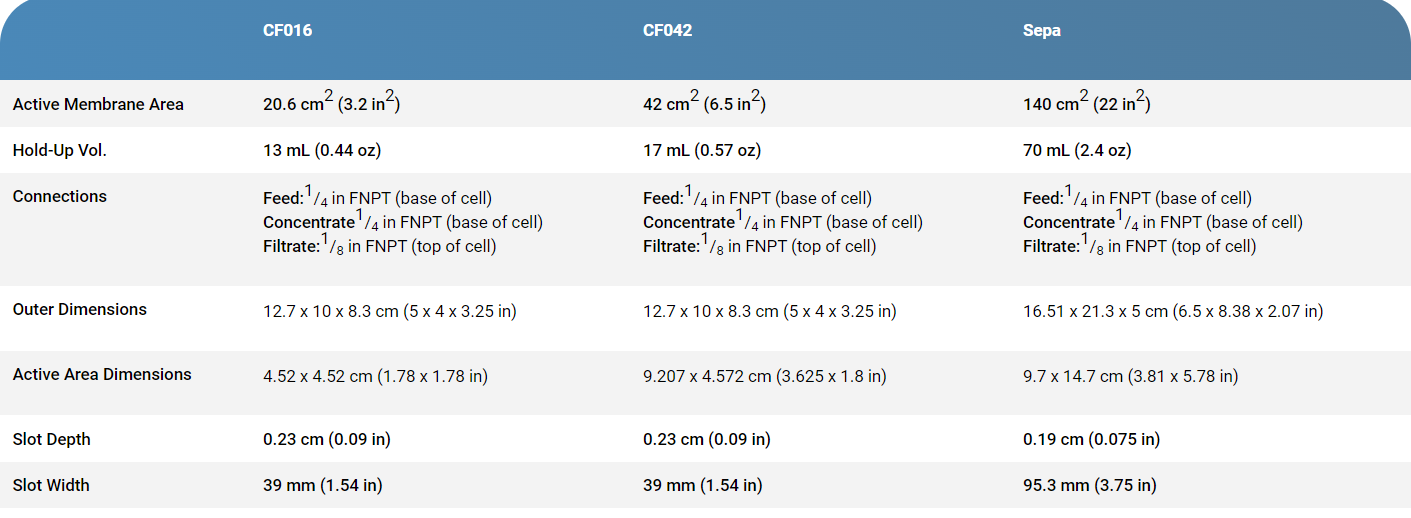

A. The Sepa CF, CF042, and CF016 test cells operate in true crossflow mode and have both concentrate and permeate streams. Depending on system design and the fluid being processed, they are operated with user selected pressure and flow parameters and allow for continuous testing and sampling.The HP4750 stirred cell is an enclosed batch system with a maximum feed volume of 300mL that is typically pressured with compressed gas. Stirred cells are operated in normal flow mode and do not have a concentrate stream. Stir bar action is used to simulate cross flow near the membrane surface.