Why does my track-etched membrane have waves?

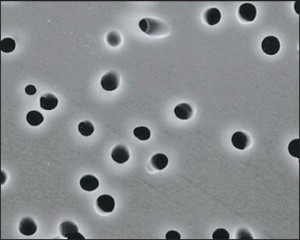

Thin film track etched membranes, commonly referred to as polycarbonate (PCTE) and polyester (PET) filters, feature a unique pore structure and optical clarity unlike most filters. A complex, two step manufacturing process involving ion bombardment of the film followed by a chemical bath results in this attractive membrane exhibiting a smooth surface interrupted with the appearance of wrinkles, or rather waves, which may be concerning to first time users.

Waves are a structural artifact of the manufacturing process for these delicate yet durable membranes, made with very thin polymer films, less than half the thickness of a human hair. During the manufacturing process, long lengths of film are necessarily unwound and rewound into large rolls, multiple times. As a result of inhomogeneities in the material and slight fluctuations in thickness and tensile strength, waves occur while winding the material during the etching process. The more the roll is wound, the more intensive the waves become because the material around the waves is locally stretched. Waves will typically disappear once the membrane is slightly tensioned, such as when using a track-etched membrane in a filter holder.

Sterlitech provides track-etched membrane filters in disc, sheet, and roll formats. Waves may be more noticeable in large discs, sheets and rolls, as the membrane area is greater. The physical processes that create these inevitable waves have no effect on the membrane pore structure, and the presence of waves does not affect the filtration performance of the track-etched membranes. Bubble point, flow, and thickness tests post product verify all membrane manufactured meets its respective specifications.

Is a track etched membrane right for your application? Contact [email protected] to discuss...

- Most Viewed Blog Articles (5)

- Company News (285)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)