What Membrane Filters are Right for Me?

Question: How do I know if a membrane process is suitable for my unique application?

Usually, researchers start with bench-scale feasibility testing.

That means using a membrane sample from a large-scale membrane module offered by commercial manufacturers and testing that in a bench-scale filtration setup.

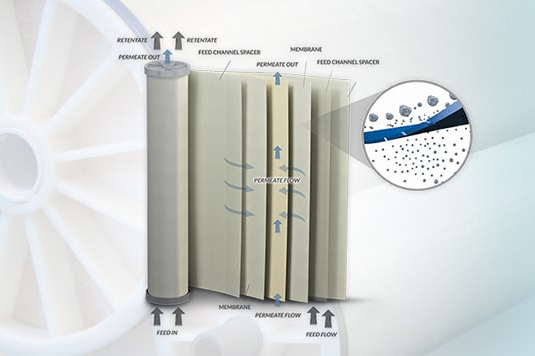

Using only a small feed volume, researchers can mimic the hydrodynamic conditions of larger-scale spiral-wound membrane modules without the actual large-scale of it. Using spacers and shims to mimic the geometry, a small system can determine which material and pore size/molecular weight cutoff (MWCO) is most effective for the application.

You can tightly control and find the optimum operating conditions to develop your separation process.

What type of filtration is your best bet?

That depends.

Microfiltration (MF) uses relatively large filtration pores - about 0.1 to one micrometer. It can reliably filter out bacteria, algae, protozoa, sediment, and similar particles.

Ultrafiltration (UF) is commonly used in the dairy industry, processing and concentrating skim milk. For separation of large macromolecules like proteins, UF is also useful in life science studies. The pore size of these membranes are 0.01 to 0.1 micrometer.

Nanofiltration (NF) membrane pore size is from about one nanometer to 10 nanometers, and are commonly used in a wide variety of applications, including the water recovery, pharmaceutical, and fine chemical industries. Divalent ions and dissolved organic molecules are examples of what NF membranes remove.

Reverse osmosis (RO) pore sizes are smaller than one nanometer, and are commonly used in seawater desalination and other water purification applications where monovalent ions, or in some cases, very small dissolved organic compounds need to be removed.

For a visual overview of the relative scales presented above, have a look at this diagram: https://www.sterlitech.com/media/pdf_downloads/f/i/filtration_spectrum.pdf.

Based on your application, one of our engineers can help determine the most suitable material and type of filtration.

Scaling up

After doing bench-scale feasibility testing, some of our customers have used our bench scale systems to do small-batch production. Others then need to scale their processes up. So how can your workplace move to a full size system using these membrane samples and coupons, and these small benchtop filtration setups?

When you are happy with your benchtop process, you can move to working with us on a larger pilot scale filtration system, or if you are confident enough, engage a commercial scale system builder to commercialize your process.

Either way, by having done bench scale feasibility testing, you will have the confidence knowing that the larger investment required in the next stage will yield the results you’re looking for.

Ready to get started? Give us a call.

- Most Viewed Blog Articles (5)

- Company News (285)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)