When selecting the right membrane for a microfiltration application, one of the most important factors to consider is membrane wettability. While hydrophobic membrane filters are ideal for air and gas filtration, they are not suitable for filtering aqueous solutions. Hydrophilic membrane filters, on the other hand, are commonly used for clarification and sterilization of water-based fluids but are not typically used for venting applications.

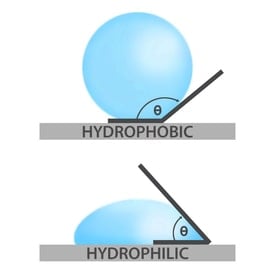

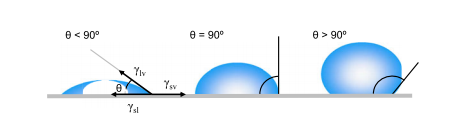

To conceptualize the forces contributing to membrane wettability, you can start by thinking of a water drop on a material’s surface.

(Yuan & Lee, 2013)

When the electrostatic attraction between the water molecules and the material is greater than the attraction between the water molecules themselves, the water drop will spread out. Here, the instantaneous angle between the edge of the drop and the surface, the water contact angle, will be <90°. Such materials are called hydrophilic, literally meaning “water loving”. The more hydrophilic the material surface, the lower the water contact angle.

When the electrostatic attraction between the water molecules and the material is less than the attraction between the water molecules themselves, the water drop will pull itself into a flattened spherical shape, with a water contact angle >90°. Such materials are called hydrophobic, literally meaning “water fearing” but more accurately meaning “water repelling”. The more hydrophobic the material surface, the greater the water contact angle.

A material’s water contact angle can be measured using a few different methods, including sessile drop (where an image of the droplet on a surface is captured and analyzed), captive bubble, and tilting plate (Yuan & Lee, 2018).

Hydrophobic membrane filters

Because of their ability to repel water and resist water wetting, hydrophobic membrane filters are commonly used as vent filters for tanks and containers, water repellent vent filters for electrical enclosures, filters for monitoring airborne contaminants, and filters to protect vacuum pumps from water aspiration. Sterlitech offers a variety of hydrophobic membrane filters, including PTFE and polypropylene.

Hydrophilic membrane filters

Sterlitech offers a broad variety of hydrophilic membrane disc and syringe filters, from inorganic silver and ceramic to polymeric nylon and polyethersulfone (PES). The applications for hydrophilic membranes are as varied as the membrane material options. They include clarification of aqueous chromatography samples; sterilization of tissue culture media, serums, buffer solutions and biological samples; and gravimetric analyses.

This video illustrates the wettability of hydrophobic membrane filters compared to hydrophilic filters.

References:

[1] Yuan, Y., & Lee, T. (2013). Contact Angle and Wetting Properties. Retrieved from https://doi.org/10.1007/978-3-642-34243-1_1

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)