Track-etched Membranes for Liposome Extrusion

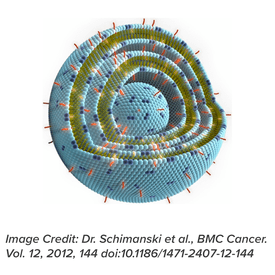

Liposomes are vesicles consisting of an aqueous core inside a hydrophobic membrane bilayer that can be used as a carrier system. They present a promising tool for the delivery of pharmaceutical agents and compounds that typically are unable to diffuse across membrane barriers. Production of liposomes allows for the incorporation of both hydrophobic and hydrophilic compounds into their structure for targeted delivery, enabling use in diagnostics, gene therapy, vaccines, cosmetics, and cancer treatment. In fact, multiple liposomal formulations of cancer therapies have already been introduced on the market.1 Potential applications extend well past drug delivery – from food production and nutritional supplements to environmental remediation.2,3

Liposomes can be prepared using extrusion, wherein a lipid suspension is forced through a microporous membrane filter over multiple passes. The membrane pore size and operating conditions determine the liposome sizes created in this process. Track-etched membrane filters – commonly polycarbonate (PCTE), but polyester (PETE) may also be used - are the filters of choice for liposome extrusion, due to precisely defined pore structures with cylindrical pores and ability to withstand the required demanding operating conditions.

Liposomes may also be prepared and sized using freeze-thaw cycles and sonication methods.1 However, a 2016 study published in Pharmaceutics found that extrusion techniques were more efficient in terms of reproducible nanosizing, compared to various sonication techniques.4 The same study also concluded that extrusion offers better size distribution homogeneity, processing speed, and a lower risk of contamination.4

There are multiple commercially available extruders that can utilize Sterlitech track-etched membrane filters. We offer a wide variety of pore sizes, allowing for the evaluation of many liposome size ranges in extrusion studies – explore all twenty pore size options for polycarbonate (from 0.01 to 30 microns). For example, researchers have previously utilized our PCTE membrane filters with 0.03 µm, 0.05 µm, 0.08 µm, 0.1 µm, 0.2 µm, 0.4 µm, and 1 µm pore sizes to create liposomes.5,6,7 If you can't find the correct filter size for your research on our website, we’re happy to explore custom-cut filter options.

References:

[1] Akbarzadeh, A., Rezaei-Sadabady, R., Davaran, S., Joo, S., Zarghami, N., & Hanifehpour, Y. et al. (2013). Liposome: classification, preparation, and applications. Nanoscale Research Letters, 8(1), 102. doi: 10.1186/1556-276x-8-102

[2] Law, B., & King, J. (1985). Use of liposomes for proteinase addition to Cheddar cheese. Journal Of Dairy Research, 52(01), 183. doi: 10.1017/s0022029900024006

[3] Gatt, S., Bercovier, H., & Barenholz, Y. (1991). Use of liposomes for combating oil spills and their potential application to bioreclamation. United States: Butterworth Publishers.

[4] Ong, S., Chitneni, M., Lee, K., Ming, L., & Yuen, K. (2016). Evaluation of Extrusion Technique for Nanosizing Liposomes. Pharmaceutics, 8(4), 36. doi: 10.3390/pharmaceutics8040036

[5] Akbarzadeh, A., Rezaei-Sadabady, R., Davaran, S., Joo, S., Zarghami, N., & Hanifehpour, Y. et al. (2013). Liposome: classification, preparation, and applications. Nanoscale Research Letters, 8(1), 102. doi: 10.1186/1556-276x-8-102

[6] Rong, X., Wang, B., Palladino, E., de Aguiar Vallim, T., Ford, D., & Tontonoz, P. (2017). ER phospholipid composition modulates lipogenesis during feeding and in obesity. Journal Of Clinical Investigation, 127(10), 3640-3651. doi: 10.1172/jci93616

[7] Huang, F., Lee, T., Chang, C., Chen, L., Hsu, W., Chang, C., & Lo, J. (2015). Evaluation of 188Re-labeled PEGylated nanoliposome as a radionuclide therapeutic agent in an orthotopic glioma-bearing rat model. International Journal of Nanomedicine, 463. doi: 10.2147/ijn.s75955

- Most Viewed Blog Articles (5)

- Company News (285)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)