Totally Tubular: Polycarbonate Membranes as Templates for Nanotubes

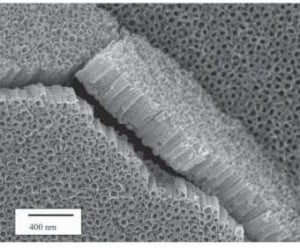

A few months ago, we added an article on our blog about how the pores are track-etched into our polycarbonate membrane filters. Track-etching results in uniform, cylindrical pores, the size and density of which can be tightly controlled by adjusting the polycarbonate’s exposure to charged particles and caustic etchants. As it turns out, the relatively uniform pores in a polycarbonate membrane make them an excellent substrate for the synthesis of nanowires and nanotubes. In the production of nanostructures, polycarbonate membranes are used like nano-scale muffin pans. A chemical precursor for the type of nanotube being produced is allowed to infiltrate the pores of the membrane by means of a solution or chemical vapor deposition. The nanotubes form in the pores as material aggregates onto the walls of the membrane. Finally, the polycarbonate membrane is removed or dissolved away, leaving behind nanotubes that are more uniform than those synthesized without one. Nanotubes are being explored for several economically important areas, such as the production of more efficient solar cells, catalysts for making ethanol from syngas (CO and H2) as this ethanol can be used as an inexpensive and environmentally friendly fuel and fuel additive, or for computer chips capable of faster processing than any current silicone-based chips. For more information about how polycarbonate membranes are used in nanostructure synthesis, check out the following links:

- Using Polycarbonate Membranes as Templates for the Preparation of Au Nanostructures for Surface-Enhanced Raman Scattering. Batista, Elisete A.; dos Santos, Diego P.; Andrade, Gustavo F. S.; Sant'Ana, Antonio C.; Brolo, Alexandre G.; Temperini, Marcia L. A. Journal of Nanoscience and Nanotechnology, Volume 9, Number 5, May 2009 , pp. 3233-3238(6) Link: https://www.ingentaconnect.com/content/asp/jnn/2009/00000009/00000005/art00064

- Heterostructured Magnetic Nanotubes. Lee, Daeyeon; Cohen, Robert E.; and Michael F. Rubner. Langmuir, 2007, 23 (1), pp 123–129 Link: https://pubs.acs.org/doi/abs/10.1021/la0612926

- Hardev Singh Virk (2011). Fabrication and Characterization of Copper Nanowires, Nanowires - Implementations and Applications, Dr. Abbass Hashim (Ed.), ISBN: 978-953-307-318-7, InTech, DOI: 10.5772/16382. Available from: https://www.intechopen.com/books/nanowires-implementations-and-applications/fabrication-and-characterization-of-copper-nanowires Link: https://www.intechopen.com/books/nanowires-implementations-and-applications/fabrication-and-characterization-of-copper-nanowires

If you want to read about another unexpected use for Sterlitech’s membrane filters, check out this past blog article where our silver membranes are used as electrodes in a fuel cell design.

- Most Viewed Blog Articles (5)

- Company News (285)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)