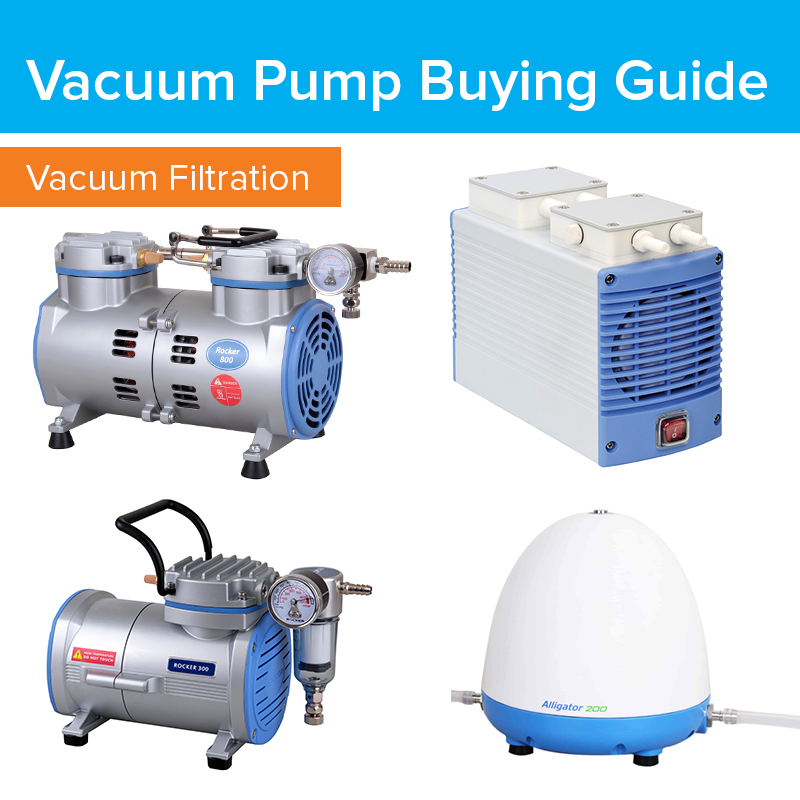

Laboratory Filtration Vacuum Pump Overview & Buying Guide

Match your Vacuum Pump to your Application

Once you’ve determined that vacuum filtration is the right option, the next step is to select the vacuum pump best suited for your application. This can seem like a daunting task, but we outlined a few considerations below to help you get started:

Q: Does your application use harsh chemical solutions such as organic solvents?

A: If so, you should select a solvent-resistant pump.

Our Recommendation: Chemker 411

Product Features: Chemically resistant, strong max vacuum, oil free, includes moisture trap

Q: Are you filtering a high viscosity liquid?

A: If yes, you will most likely have to consider a pressure filtration system. However, if you do use vacuum filtration, then select a pump capable of achieving the deepest vacuum (lowest absolute pressure).

Product Features: Strong max vacuum, oil free, includes moisture trap/overflow protection

Our Recommendation: Chemker 410 (for solvent solution)

Product Features: Chemically resistant, strong max vacuum, oil free

Q: Do you have a high-flow application? Are you using large holders (≥90mm), multiple holders (vacuum manifold), and/or high flow filtration media?

A: If the answer is yes to any of the above, then select a pump with a high flow rate.

Our Recommendation: Rocker 800

Product Features: Highest flow rate, oil free

Q: Do you have limited space for your vacuum filtration system?

A: If so, a liquid pump may best suit your needs.

Our Recommendation: Alligator 200 ( Call 1-877-544-4420 OR email [email protected] for more info)

Product Features: No receiving flask required, transfers liquid directly to waste - saving valuable time and space, oil free

More Vacuum Pump Tips

Understanding Maximum Vacuum Ratings: Rocker vacuum pumps have absolute pressure maximum vacuum ratings. This means that the ratings are relative to zero pressure; so the smaller the rating value, the deeper the vacuum. The Rocker maximum vacuum ratings have units of millibars (mbar), but absolute pressure maximum vacuum ratings can be reported in other units, such as torr.

Some manufacturers report maximum vacuum ratings relative to atmospheric pressure. The rating value is the difference in pressure from atmospheric; therefore the greater the rating value, the deeper the vacuum. In this instance, the ratings typically have units of inches of mercury (inHg) or millimeters of mercury (mmHg). While not commonly indicated, it is understood that these ratings are negative with respect to atmospheric pressure.

Cylinder Heads: A visual cue to look for when shopping for a vacuum pump is the number of cylinder heads. More cylinder heads are indictive of greater capacity. Also, cylinder heads piped in series equate to deeper maximum vacuum while cylinder heads piped in parallel denote higher maximum flow.

Useful Features to Consider

Oil-free: Dry (oil-free) vacuum pumps do not need a lubricant or require regular oil changes, which helps you save on time and maintenance costs. It also eliminates the possibility of oil leaks in the installed location.

Moisture trap with Overflow protection: Located in the air inlet, the filter cartridge traps particles and moisture to protect and prolong the life of the pump. Additionally, overflow protection prevents liquid from being sucked into the pump, preventing damage to the motor and internal components. Certain Rocker series vacuum pumps come equipped with both features.

Sterlitech is a distributor of Rocker Scientific Co., Ltd. products. Established in 2007, Rocker provides a variety of professional vacuum filtration solutions for laboratory and industrial customers in the fields of food, water, micro-organisms testing, molecular biology lab and purification.

- Most Viewed Blog Articles (5)

- Company News (285)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)