Leave it to Google to shine a light on our next generation of young scientists! As we start getting ready for the 2017 academic year, Sterlitech decided to look back at last year’s Google Science Fair awards. One group of clever kids caught our attention by winning the 2016 Scientific American Innovator Award with a subject near and dear to our hearts: filtration. They made filters from a unique source – waste Styrofoam packing!

The trio of middle school students from Columbus, Ohio, came up with the idea after one of the three made a trip to Central America the prior year. The student was surprised at the volume of Styrofoam trash that littered the beaches and wondered if there was something that could be done. Further research into the use of Styrofoam in the United States showed an estimated 25% of our landfill waste space is occupied by Styrofoam packing alone– close to 1.9 Billion pounds!

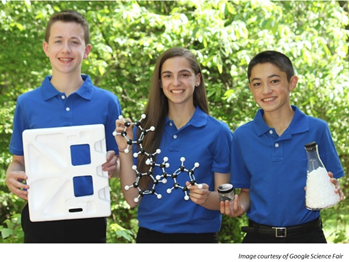

The Ohio eighth-graders (Ashton Cofer, Luke Cray, and Julia Bray) decided to put their heads together and enlist the help of scientists from Battelle Memorial Institute and the Ohio State University to determine if the Styrofoam could be easily converted from a waste product into a useable product. Since Styrofoam is mostly carbon, they asked, “What usable things can be made from carbon?”. The simple and easy answers are graphite, diamonds, and activated carbon. Activated carbon is a common raw material used in air and water filtration systems as it does a very good job of absorbing pollutants and contaminants. So why not start there?

Styrofoam is a type of expanded polystyrene, its polymer chains composed of over 92% carbon. The current process of recycling Styrofoam into new packing material typically results in carryover of impurities. These impurities often make the finished product more expensive and undesirable when compared to new Styrofoam. The trio of students, and their mentors, discussed the problem at length and came up with an experimental process to convert the waste Styrofoam into activated carbon. They revised the conversion process several times to optimize the activated carbon format and then tested the activated carbon against common water pollutants such as iron, copper, and chlorine. All their hard work yield ultimately yielded positive results! Their newly made Styro-Filter material reduced iron by 98%, reduced copper by 90%, and chlorine by 20%. These results are comparable to conventional activated carbon already employed in water filtration. Good job kids!

Sterlitech congratulates Ashton, Luke, and Julia for their hard work and resourcefulness at tackling a significant waste problem and turning it into a useful technology. We’re looking forward to this year’s entrants in the 2017 competition!

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)