FAQ: Clarification of Fruit (Apple) Juice

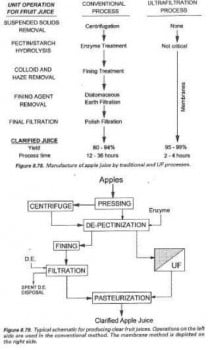

Over the years we have seen an increased use of filtration equipment in juice processing, particularly regarding ultrafiltration (UF) or microfiltration (MF)for the clarification of apple juice. Since it has been demonstrated that membrane filtration can produce yields of 95%-99% - compared to only 80-94% through conventional processes – it is no wonder that filtration methods are growing in prevalence. The greater yield combined with the reduced time and labor costs have translated to hundreds of thousands of dollars saved for juice processing plants! If you are considering juice filtration, here a couple of tips to keep in mind:

- The juice must be clear. Of the four common types of apple juice produced – natural, crushed, clarified, and clear – only clear juice is suitable for membrane processing.

- Consider ceramic membranes. More and more fruit juice installations are installing ceramic membranes. While these do have a higher cost than other materials, they do offer a higher flux, much longer life, and better resistance to aggressive processing and cleaning conditions.

- Know your operation. Since fruit juices have a very low level of retained solids, the optimum mode of operation is the modified batch operation with a partial recycle of retentate.

- Not just for apples. Other fruit and vegetables that have benefited from membrane filtration include: apricot, carrot, cherry, cranberry, grape, lemon, lime, orange, peach, passion fruit, and tomato.

References: Ultrafiltration and Microfiltration Handbook. Cheryan, Munir. Technomic Publishing Company, 1998. Microfiltration and Ultrafiltration: Principles and Applications. Zemon, Leos & Zydney, Andrew. Marcel Dekker, 1996.

- Most Viewed Blog Articles (5)

- Company News (285)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)