Don’t get Blinded when Using the Track-Etch Membrane Filters

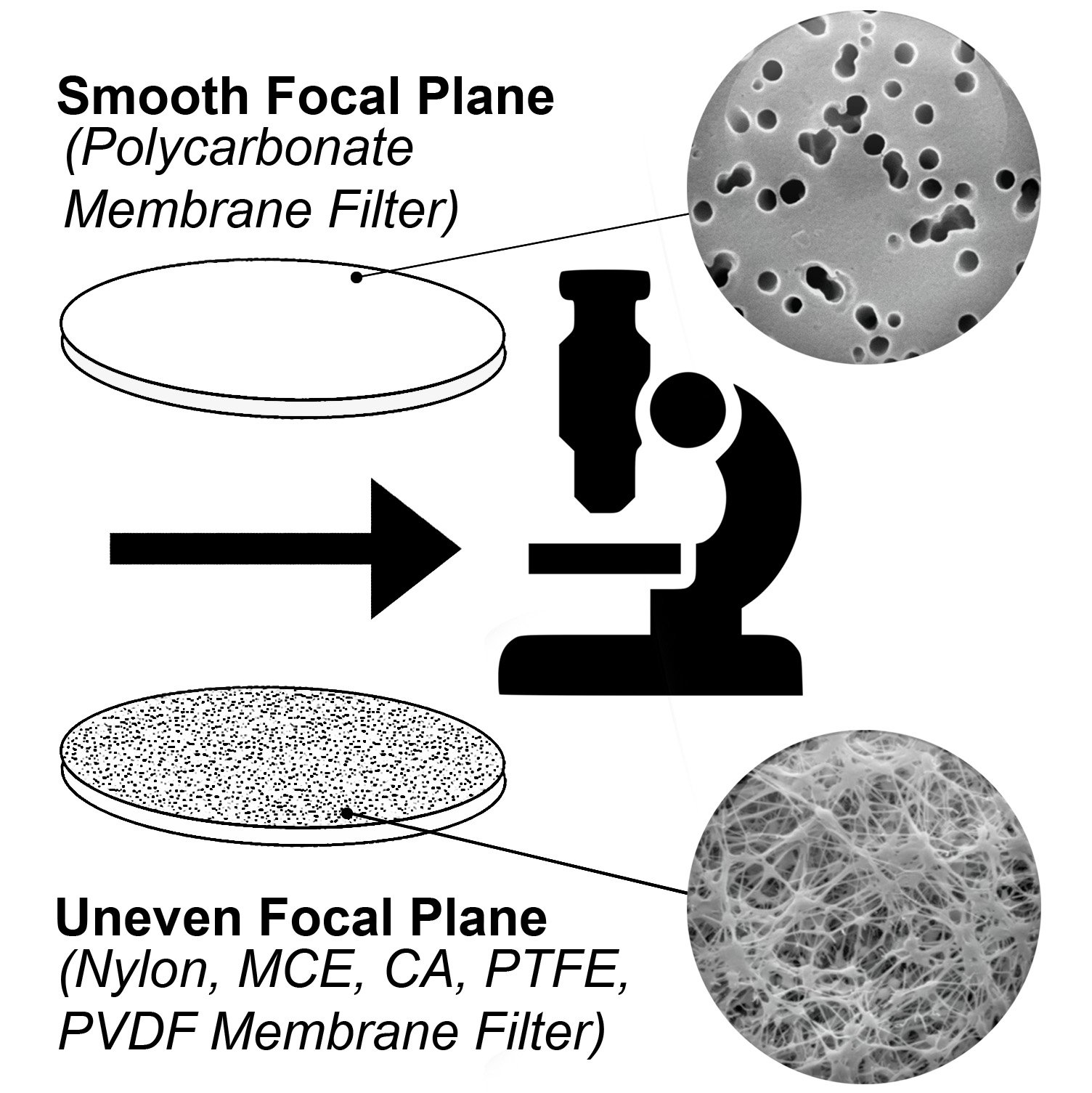

Sterlitech’s polycarbonate and polyester track-etch membrane filters are a unique product that find use in numerous applications. They possess clean cylindrical pores that transverse the membrane surface from one side to the other. As a result of this unique feature, the pore density must be much lower compared to almost all other standard thin-film membranes such as Nylon, PTFE, PVDF, and more. Particulates either pass through the pores in track-etch filters, or remain on the surface. Almost never do they become embedded within the pore’s interior. But what happens when these filters are needed for your project and the particles being filtered occlude the opening of the pores? This effect is called pore blinding; and you may ask “But what can be done?”

Fear not brave scientist! In most applications, the track-etch filters will work fine on their own. But if a difficult particulate is clogging up your filter too soon, consider use of our Polyester Drain Discs. These discs act as a pre-filter to prevent the dreaded pore blinding from stopping your filtration run and allow you to stand head and shoulders above your competitors. The drain discs keep larger material off the pores and out of the way, so the filters can do their job. In addition, the drain discs also act as a membrane support when using two track-etch filters in series (one on top of the other) for a step-wise separation method. These handy discs are available in several different pore sizes to pair with the track-etch filters.

Need a little help in getting the blinders off the track-etch filters? Please contact Sterlitech’s sales team for help at [email protected].

- Most Viewed Blog Articles (5)

- Company News (284)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)