Back to the Basics: Membrane Process and Development (MP&D)

Sterlitech is an innovator in the development of bench-scale cross flow test cells for membrane development, studies, and small scale processing applications. But what does that actually mean?

Bench-scale: The term “bench” is shorthand for lab or work bench, and describes the coveted and often constrained space upon which most researchers or technicians use their equipment. Our equipment is ideal for the scale of work typically conducted in a lab, processing 300 ml to 6.7 L (5 Gal).

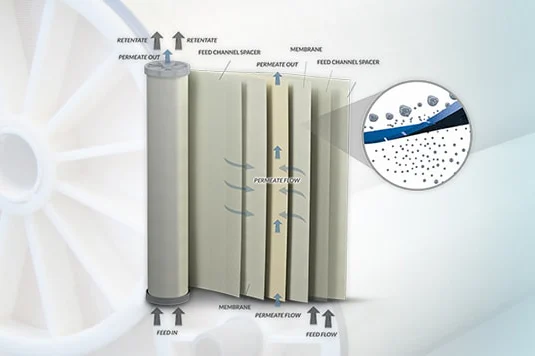

Flat Sheet Membranes: One of three major components of a spiral wound element. Repeating layers of Membrane, feed spacer, and permeate carrier are rolled to produce an “element” that is used in full scale processing applications. Single, small cuts of membrane are commonly referred to as “coupons” and are a cost effective approach to sampling. Membrane attributes vary in porosity, flux, pH range, and chemical compatibility.

Crossflow Test Cells: Circular or rectangular assemblies that accommodate a single layer of membrane during tangential flow operation. The cells are specifically designed to simulate the flow dynamics of larger, commercially available spiral wound elements, but at a smaller scale.

Working at this scale utilizes fewer resources (ie less feed solution and smaller membrane area), which make them ideal for feasibility studies, developing and testing membranes, or small batch processing.

Sterlitech's membrane test cells can provide flexibility in testing either microfiltration, ultrafiltration, nanofiltration and reverse osmosis applications across various industries; from bio-pharm, food & beverage to desalination.

Each cell is integratable into existing Sterlitech crossflow filtration skids and systems. Click here for more details on how to get started fitting the test cell into a full crossflow system.

- Most Viewed Blog Articles (5)

- Company News (285)

- Emerging Technologies (64)

- Microbiology and Life Science News (93)

- Water and Fluid Separation News (97)

- Filtration Resources (93)

- Product News (19)

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/blog/cache/300x200/magefan_blog/b4.jpeg)