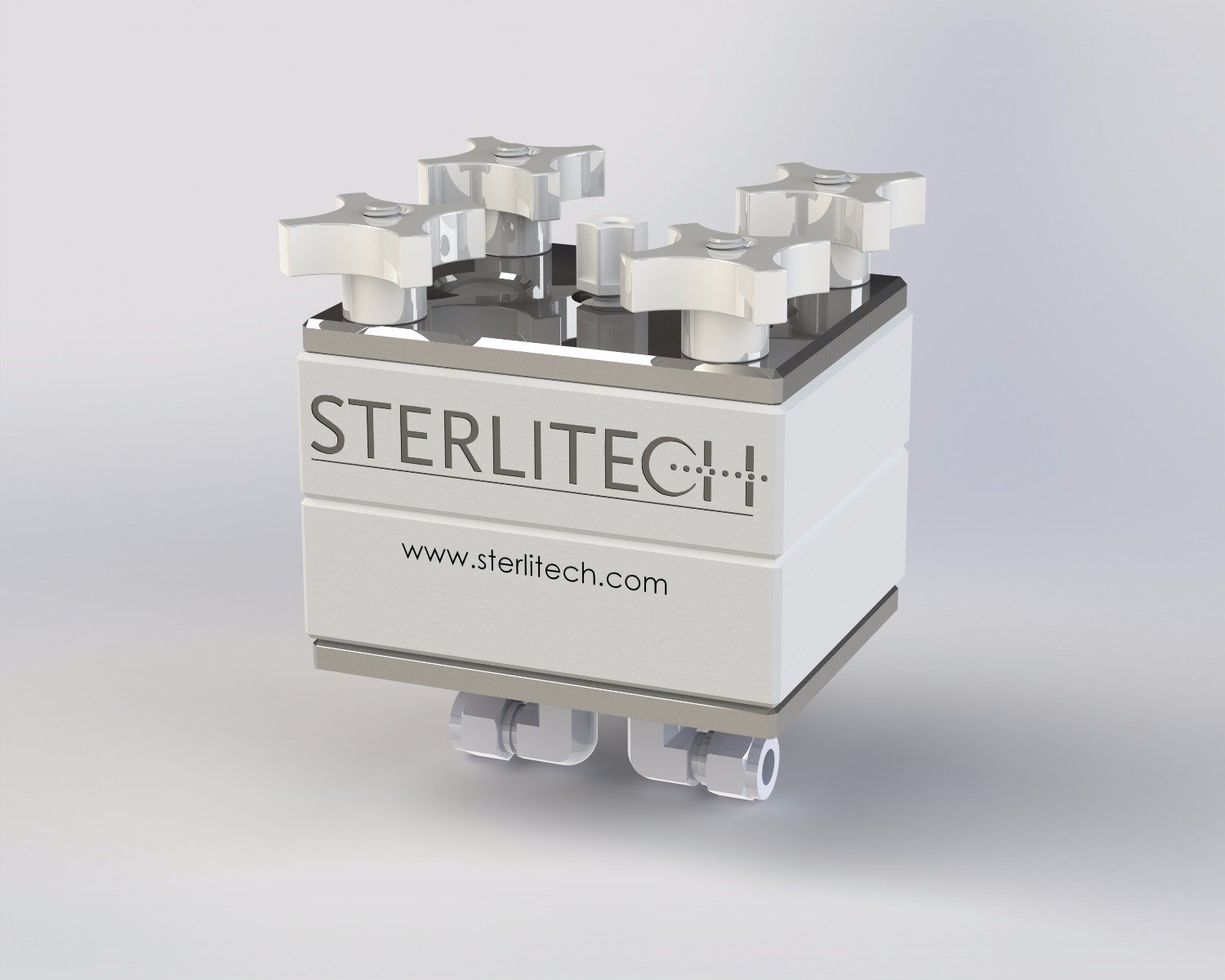

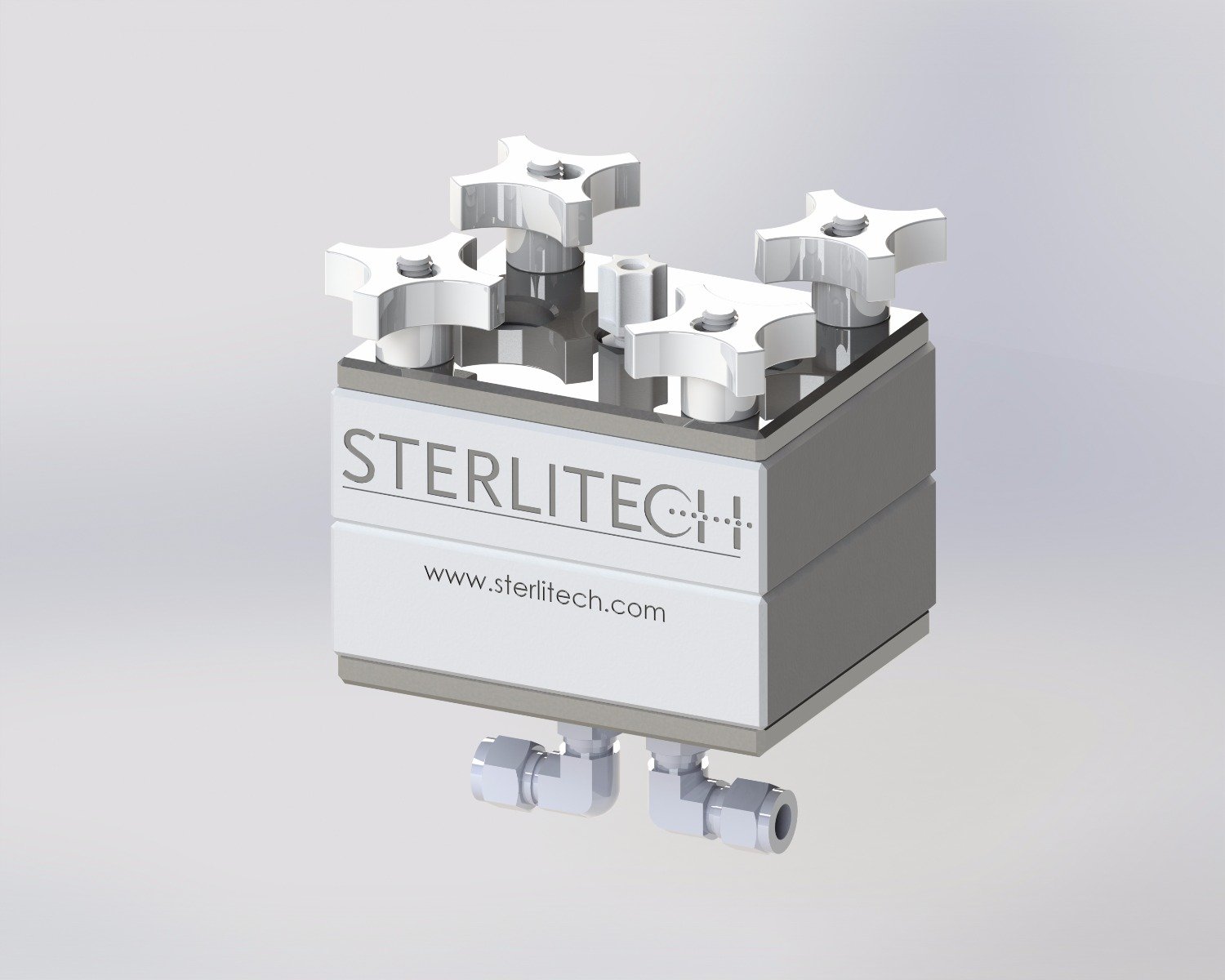

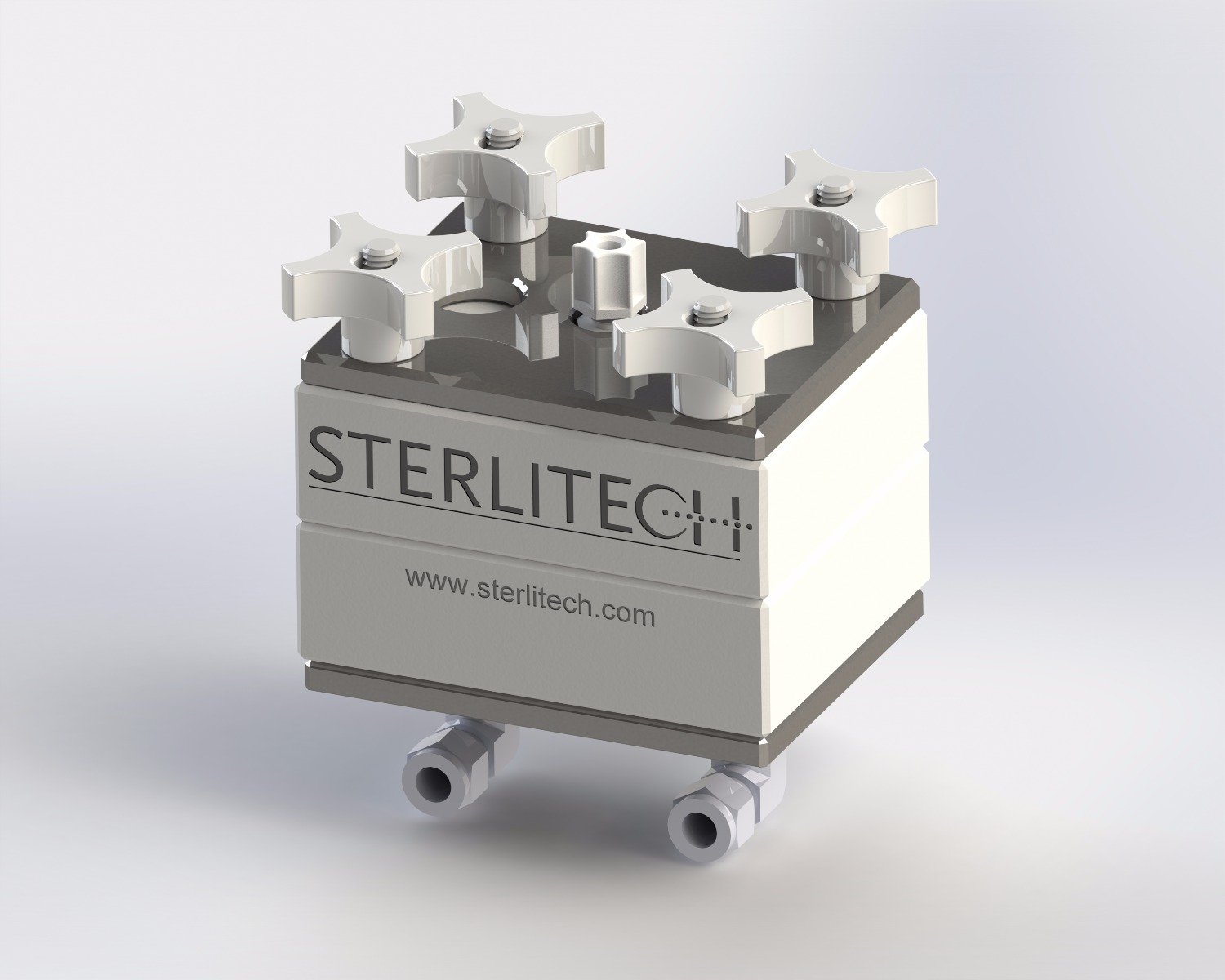

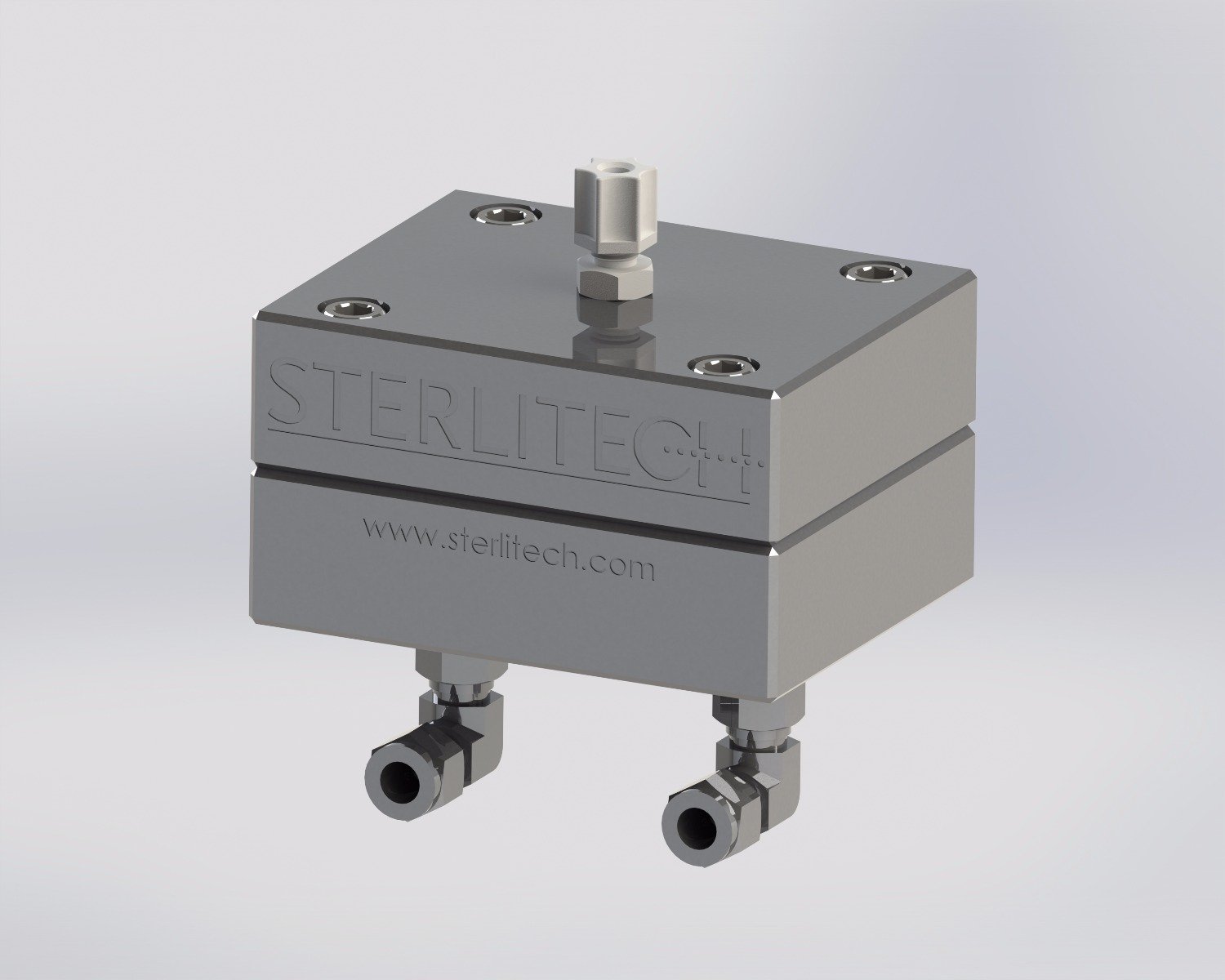

CF016 Cell Assembly, Crossflow, PTFE (CF016P)

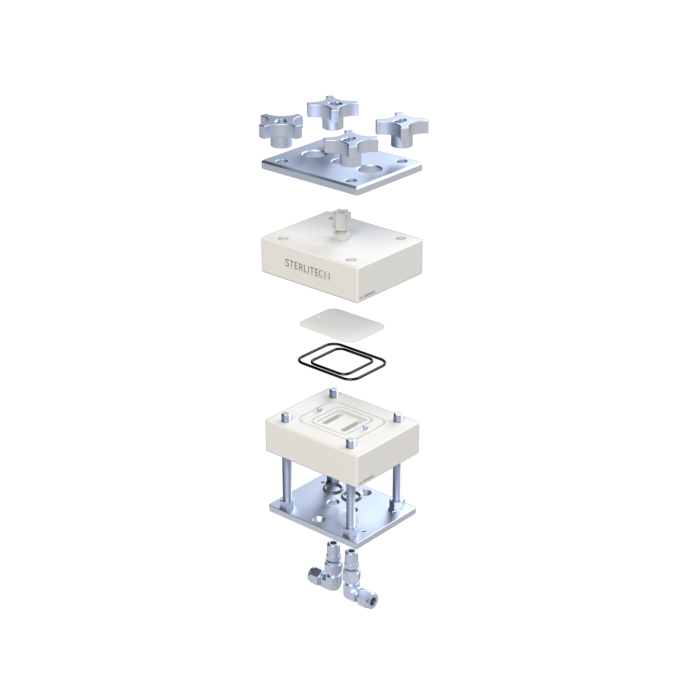

The CF016 cell is a bench-scale cross/tangential flow cell that provides fast and accurate performance data with minimal amounts of membrane, product, expense or time.

CF016 cell has a membrane active area of 20.6 cm2 (3.2 in2).

CF016, PTFE, has a a maximum operating pressure of 400 psi (27.6 bar) and is suitable for chemically resistant applications.

Details

The Sterlitech CF016 membrane cell is a lab scale cross flow filtration unit designed to provide fast and accurate performance data with minimal amounts of product, expense, and time.

CF016 Membrane Cell Product Availability:

- Cross flow cell units available in Delrin, PTFE, Stainless Steel, or Acrylic

- 1000 psi (69 bar) max operating pressure (PTFE and Acrylic versions are 400 psi)

- Active membrane area: 20.6 cm2

Please note: A feed flow pump is required to operate the CF016 cross flow cell unit. We recommend the Hydracell pump by Wanner Engineering, which is a positive displacement, diaphragm pump designed for high pressure, lower flow applications. When ordering, be sure to specify the power requirements for the motor. The minimum power available is 110V, 60 Hz. 220 V and 50 Hz motors are also available. There may be an additional cost if a variable speed drive is required.

Applications

Cross/tangential flow test cells are typically used in membrane applications such as :

- Biological or biopharmaceutical processing

- Concentration of fruit juices and extracts

- Food and beverage processing

- Desalination of brackish water or seawater

- Purification of rinse water in electroplating tanks

- Municipal or industrial water and wastewater purification

Specifications

Specifications by Material:

| Product Family | Innovator | Explorer | Developer | |||||||||

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Material |

Acetal (Delrin) |

316 Stainless Steel |

Virgin PTFE |

Acrylic |

Acetal (Delrin) |

316 Stainless Steel |

Virgin PTFE |

Acrylic |

Hastelloy™ |

316 Stainless Steel |

Acrylic |

Hastelloy™ |

|

Maximum Bolts Torque Setting (in-lbs) |

60 |

NA |

15 |

45 |

60 |

NA |

15 |

45 |

70 |

NA |

45 |

70 |

|

Maximum Fittings Torque Setting (in-lbs) |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max Pressure |

69 bar |

69 bar |

27.6 bar |

27.6 bar |

69 bar |

69 bar |

27.6 bar |

27.6 bar |

69 bar |

69 bar |

15.2 bar |

69 bar |

|

Max Temperature |

82°C |

150°C |

260°C |

88°C |

82°C |

150°C |

260°C |

88°C |

150°C |

150°C |

88°C |

150°C |

General Cross Flow Cell Specifications:

| CF016 | CF042 | Sepa | |

|---|---|---|---|

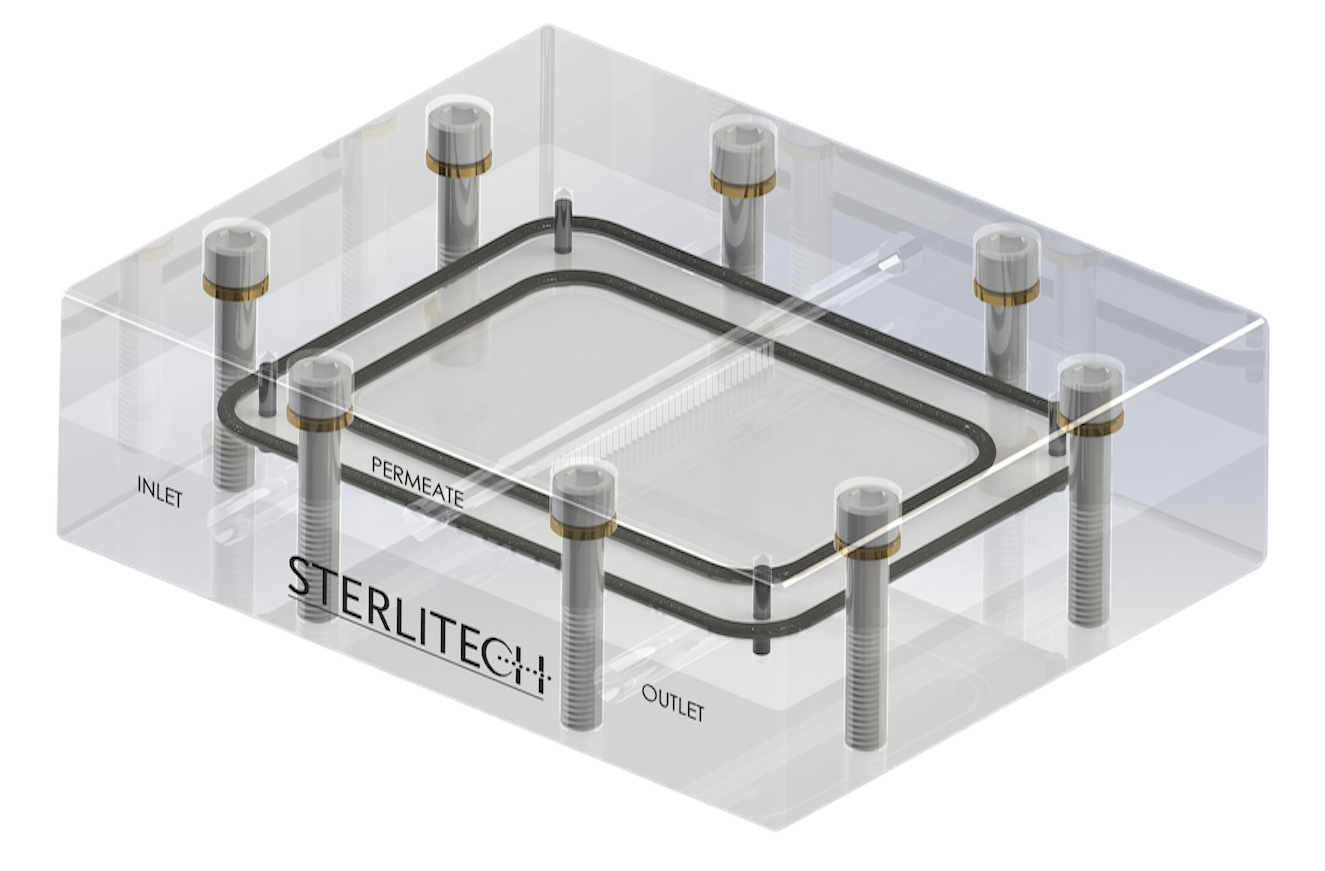

| Active Membrane Area | 20.6 cm2 (3.2 in2) | 42 cm2 (6.5 in2) | 140 cm2 (22 in2) |

| Hold-Up Vol. | 13 mL (0.44 oz) | 17 mL (0.57 oz) | 70 mL (2.4 oz) |

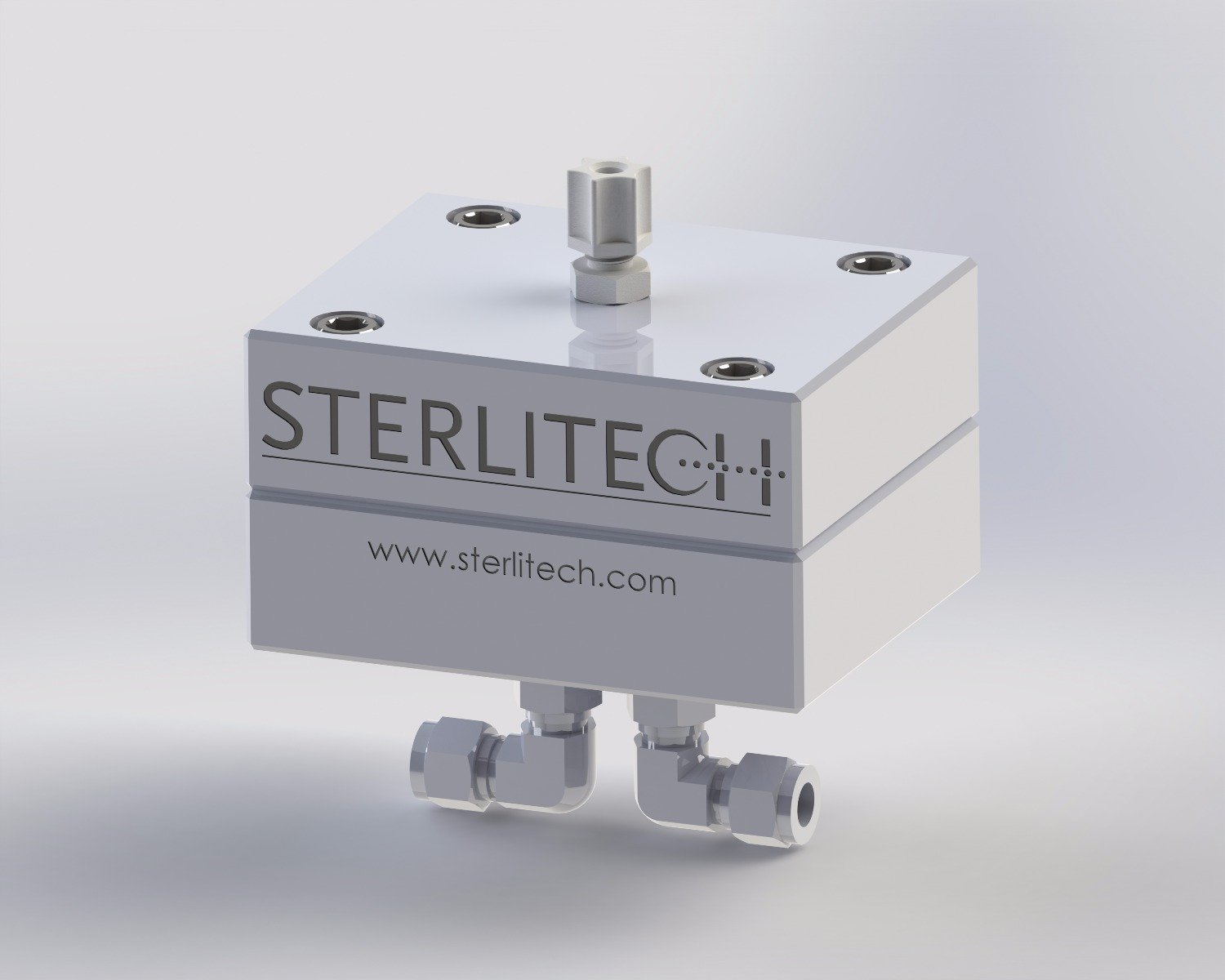

| Connections |

Feed:1/4 in FNPT (base of cell) |

Feed:1/4 in FNPT (base of cell) |

Feed:1/4 in FNPT (base of cell) |

| Outer Dimensions |

12.7 x 10 x 8.3 cm (5 x 4 x 3.25 in) |

12.7 x 10 x 8.3 cm (5 x 4 x 3.25 in) |

16.51 x 21.3 x 5 cm (6.5 x 8.38 x 2.07 in) |

| Active Area Dimensions |

4.52 x 4.52 cm (1.78 x 1.78 in) |

9.207 x 4.572 cm (3.625 x 1.8 in) |

9.7 x 14.7 cm (3.81 x 5.78 in) |

| Slot Depth | 0.23 cm (0.09 in) | 0.23 cm (0.09 in) | 0.19 cm (0.075 in) |

| Slot Width | 39 mm (1.54 in) | 39 mm (1.54 in) | 95.3 mm (3.75 in) |

Bench System - Sterlitech

Analog Skid - Sterlitech

Frequently Asked Questions

Frequently Asked Questions

Q: Are your PP spacers FDA compliant?

Yes, our Bi-Planar Feed Spacer Mesh is extruded from FDA compliant polypropylene.

Q: Why is the flat sheet membrane I'm using measuring a flux value less than the published flux value?

Flow characteristics for a spiral element and flat sheet membrane are significantly different and are really only comparable on a qualitative basis. Variability in the membrane manufacturing process, differences in water composition, test procedures, and test equipment, used in a factory, laboratory, or elsewhere, will impact water flux results.

Q: What are the available materials of construction for the Sterlitech crossflow test cells?

The Sterlitech bench-scale crossflow test cells are available in a variety of materials to suit most applications:

- Stainless Steel

- PTFE

- HastelloyTM

- Delrin (natural acetal copolymer)

- Acrylic

Addtionally, there are a variety of available o-ring seals including Buna-N, EPDM, Viton, FEP encapsulated Viton, and FFKM (Markez).

Q: How do I install/remove permeate fittings or other plastic NPT fittings?

Sterlitech recommends to install all plastic fittings by hand using PTFE tape. If a plastic NPT or compression fitting starts to leak during operational testing, tighten the fitting carefully until the leaking stops. Excessive tightening may break the fitting or damage other components.

If the fittings is broken and stuck in the cell top, use a spiral flute extractor bit or similar tool to release the portion of the fitting in the cell top. If the cell top becomes cracked from removal efforts, a replacement can be purchased.

Q: I have noticed that the flat sheet membranes come in sizes described as CF016, CF042, and Sepa CF. What are these sizes?

These membrane sizes are intended for use in the bench-scale crossflow test cells offered by Sterlitech. Please see list of flat sheet membranes we offer and their dimensions:

- HP4750 Stirred Cell: 47 mm (1.85") discs

- CF016 cell: 58 x 75mm (2.26 x 2.95") coupons

- CF042 cell: 56 x 115 mm (2.20 x 4.53") coupons

- Sepa CF cell: 140 x 190 mm (5.51 x 7.48") coupons

- CF047 circular cell: 47mm discs

- CF090 circular cell: 90 mm discs