What is Liposome Extrusion?

Liposomes are defined as closed, spherical lipid bilayer vesicles that form an internal cavity and serve as nanocarriers of aqueous solutions and a wide range of bioactive molecules. It forms when tissue is damaged resulting in exposure of the lipid bilayer that folds back on itself, encapsulating a small packet of whatever solution it forms in it. These are then used in studying cell membranes and organelles by embedding different proteins and solutions into the lipid bilayer and mostly specific to drug delivery, gene research and cosmetics.

Liposome extrusion is crucial in producing unilamellar vesicles with a homogeneous size distribution and the most efficient method of nanosizing liposomes. The homogeneity of the liposome sizes is crucial to prolong the liposome circulation time and maintain its strength during storage. Moreover, liposomes with consistent size characteristics can exhibit better control over drug release rates and increased cellular uptake.

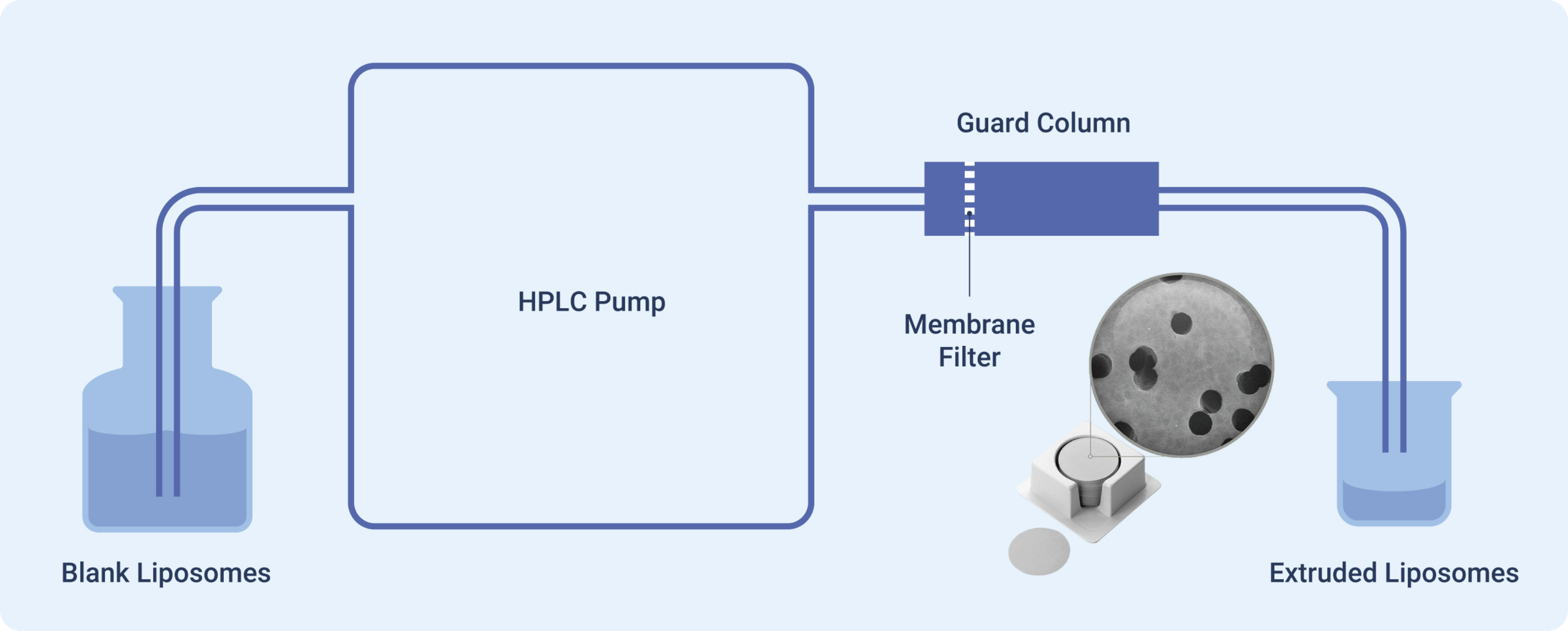

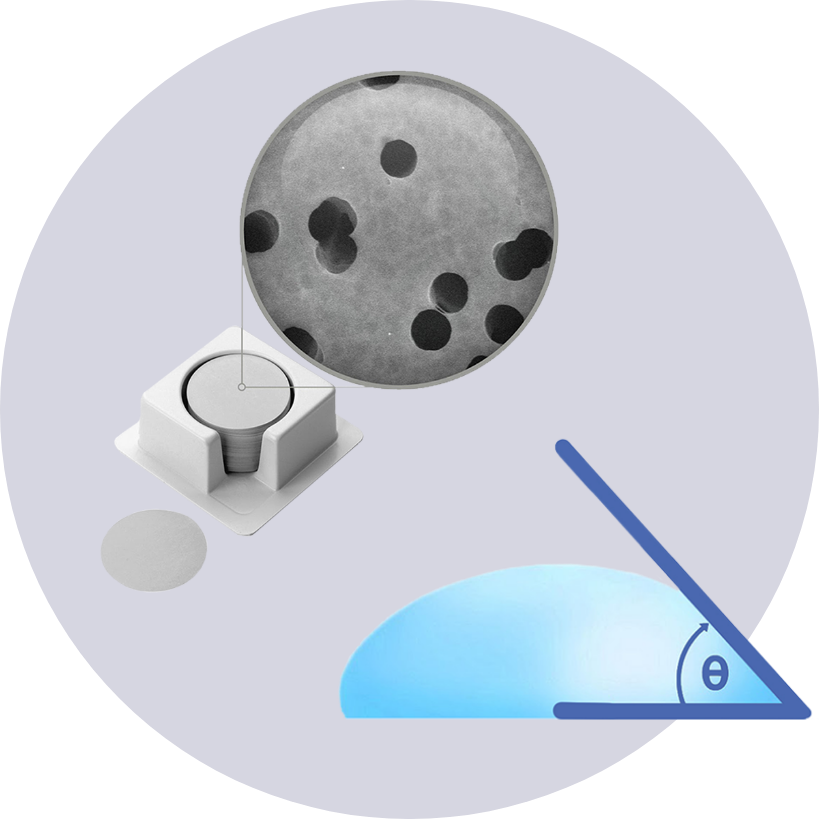

Extruder Diagram, a machine equipped with a pump which pushes fluids through the membranes:

Source: Evaluation of Extrusion Technique for Nanosizing Liposomes (Ong et al., 2016)

Using PCTE Filters for Liposome Extrusion

Drug Delivery

Liposomes can be loaded with drugs and delivered to specific tissues or cells. By controlling the size and surface properties of the liposomes, drug release can be controlled and targeted delivery can be achieved.

Vaccine Delivery

Liposomes can be used as carriers for vaccines to enhance their efficacy. The liposomes can protect the vaccine from degradation and enhance its delivery to immune cells, leading to a stronger immune response.

Gene Therapy

Liposomes can be used as carriers for gene therapy, delivering genetic material to specific cells. Liposome extrusion can be used to prepare liposomes with a specific size and surface charge, which can enhance their uptake by target cells.

Diagnostics

Liposomes can be used in diagnostic assays to enhance sensitivity and specificity. By incorporating liposomes into assays, the detection limit of the assay can be increased, leading to more accurate results.

Food and Beverage

Liposome extrusion is a technique used in the food and beverage industry to encapsulate and deliver active ingredients such as vitamins, flavors, and nutraceuticals. It has been used in the development of functional foods and beverages that provide health benefits beyond basic nutrition.

Cosmetics

In the cosmetics industry, liposome extrusion helps create products with enhanced penetration and even distribution of active ingredients on the skin.

Process of Using Filters for Liposome Extrusion

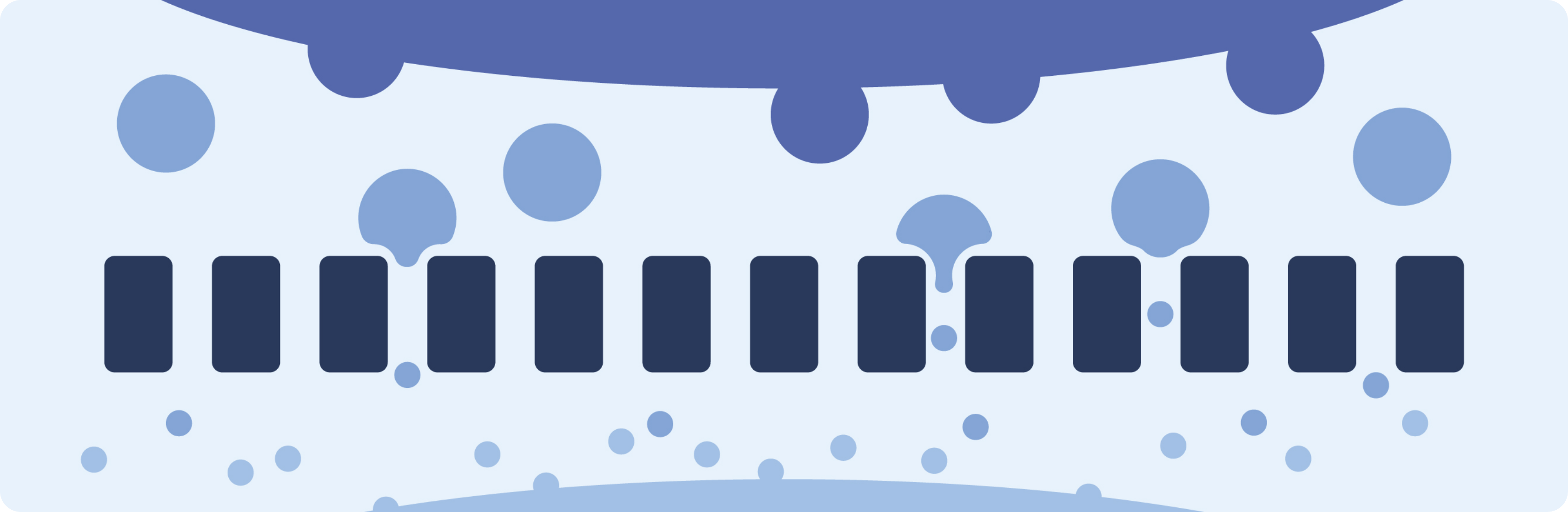

Liposomal suspension is pushed through the membrane filter 3-10 times with 1-9mL per minute flow rate.

The target flow rate is set based on pore size/target liposome size. Size distribution of liposomes can be made quite narrow, particularly by recycling the material through the selected-size filter several times. Pores are blocked when the liposome sizes are substantially greater than the membrane pore sizes.

Methods of Application

Liposome extrusion can be done in two primary methods: Manual and Automated. Both of which are a process wherein the liposome suspension is passed through a membrane filter of defined pore size. Prior to extrusion through the final pore size, the suspensions are disrupted either by several freeze-thaw cycles or by prefiltering the suspension through a larger pore size which helps to prevent the membrane to accumulate other unwanted material and improves the uniformity of the size distribution after the extrusion procedure.

During manual extrusion, the liposome suspension passed through the polycarbonate membrane by using a syringe or an extruder device. The pore size of the utilized polycarbonate membrane filter will determine the resulting liposome size. This manual procedure is suitable for small scale research or production since it was more economical and very straightforward.

However, if automated, there is an extruder, a machine equipped with a pump which pushes fluids through the membranes. This machine Is computer-controlled that will check and regulate the pressure and temperature during the process. This automated procedure will provide greater reproducibility and is ideal for large-scale production and more complex formulation.

Liposome Extrusion

Sterlitech Liposome Extrusion Products

PCTE Hydrophilic Membranes

Hotplate Stirrers

Polyester Drain Discs

Why Use Sterlitech PCTE Filters for Liposome Extrusion

PCTE Characteristics

- Smooth, flat surface

- Thin (6-24 microns thick)

- Homogeneous and sharply defined pore sizes

- Surface retention

- The number of tracks per square centimeter (pore density) is precisely defined by the ion beam intensity and by the rewinding speed of the polymer film

- Precise and controlled pore size and shape is obtained by varying etching conditions: time, temperature and strength of solutions. Negligible absorption and adsorption of filtrate; non-hygroscopic

PCTE membranes for liposome extrusion

- Must be thin (<12 microns thick) PCT membranes

- Must be high pore density and high flow rate

When switching membrane manufacturers, it is important to requalify the membrane and resulting liposome size. FDA approval may be needed.

Polycarbonate Membranes for Liposome Extrusion*

| SKU | Pore Size (μm) | Diameter (mm) | Pack Size |

|---|---|---|---|

| PCT019030 | 0.01 | 90 | 30 |

| PCT0114220 | 0.01 | 142 | 20 |

| 1270090 | 0.03 | 19.05 | 100 |

| PCT0039030 | 0.03 | 90 | 30 |

| PCT00314220 | 0.03 | 142 | 30 |

| PCT00329320 | 0.03 | 293 | 20 |

| 1270015 | 0.05 | 19.05 | 100 |

| PCT0059030 | 0.05 | 90 | 30 |

| PCT00514220 | 0.05 | 142 | 20 |

| PCT00529320 | 0.05 | 293 | 20 |

| 1270091 | 0.08 | 19.05 | 100 |

| PCT0089030 | 0.08 | 90 | 30 |

| PCT00814220 | 0.08 | 142 | 20 |

| PCT00829320 | 0.08 | 293 | 20 |

| 1270193 | 0.1 | 19.05 | 100 |

| 1270016 | 0.1 | 19.05 | 100 |

| PCT019030 | 0.1 | 90 | 30 |

| PCT0114220 | 0.1 | 142 | 20 |

| PCT0129320 | 0.1 | 293 | 20 |

| PCT00513100 | 0.2 | 19.05 | 100 |

| PCT00529320 | 0.2 | 90 | 30 |

| PCT0053001 | 0.2 | 142 | 20 |

| PCT00547100 | 0.2 | 293 | 293 |

| 1270018 | 0.4 | 19.05 | 100 |

| PCT049030 | 0.4 | 90 | 30 |

| PCT0414220 | 0.4 | 142 | 20 |

| PCT0429320 | 0.4 | 293 | 20 |

| PCT069030 | 0.6 | 90 | 30 |

| PCT0614220 | 0.6 | 142 | 20 |

| PCT0629320 | 0.6 | 293 | 20 |

| 1270019 | 0.8 | 19.05 | 100 |

| PCT089030 | 0.8 | 90 | 30 |

| PCT0814220 | 0.8 | 142 | 20 |

| 1270092 | 1 | 19.05 | 100 |

| PCT109030 | 1 | 90 | 30 |

| PCT1014220 | 1 | 142 | 20 |

| PCT1029320 | 1 | 293 | 20 |

| PCT209030 | 2 | 90 | 30 |

| PCT2014220 | 2 | 142 | 20 |

| PCT2029320 | 2 | 293 | 20 |

| PCT309030 | 3 | 90 | 30 |

| PCT3014220 | 3 | 142 | 20 |

| PCT3029320 | 3 | 293 | 20 |

| PCT509030 | 5 | 90 | 30 |

| PCT5029320 | 5 | 293 | 20 |

| PCT5014220 | 5 | 142 | 20 |

| PCT809030 | 8 | 90 | 30 |

| PCT8029320 | 8 | 293 | 20 |

| PCT1009030 | 10 | 90 | 30 |

| PCT10014220 | 10 | 142 | 20 |

| PCT1409030 | 14 | 90 | 30 |

| 1270176 | 20 | 90 | 30 |

| PCT2509030 | 25 | 90 | 30 |

| PCT3009030 | 30 | 90 | 30 |

*Other cut sizes available