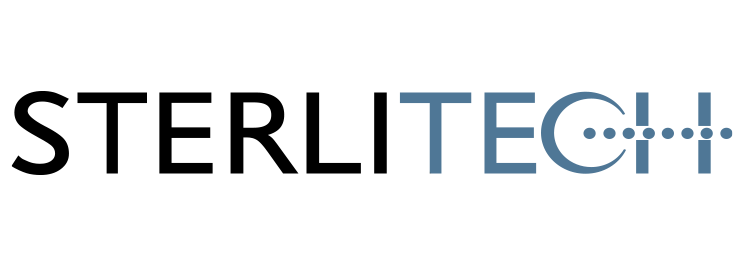

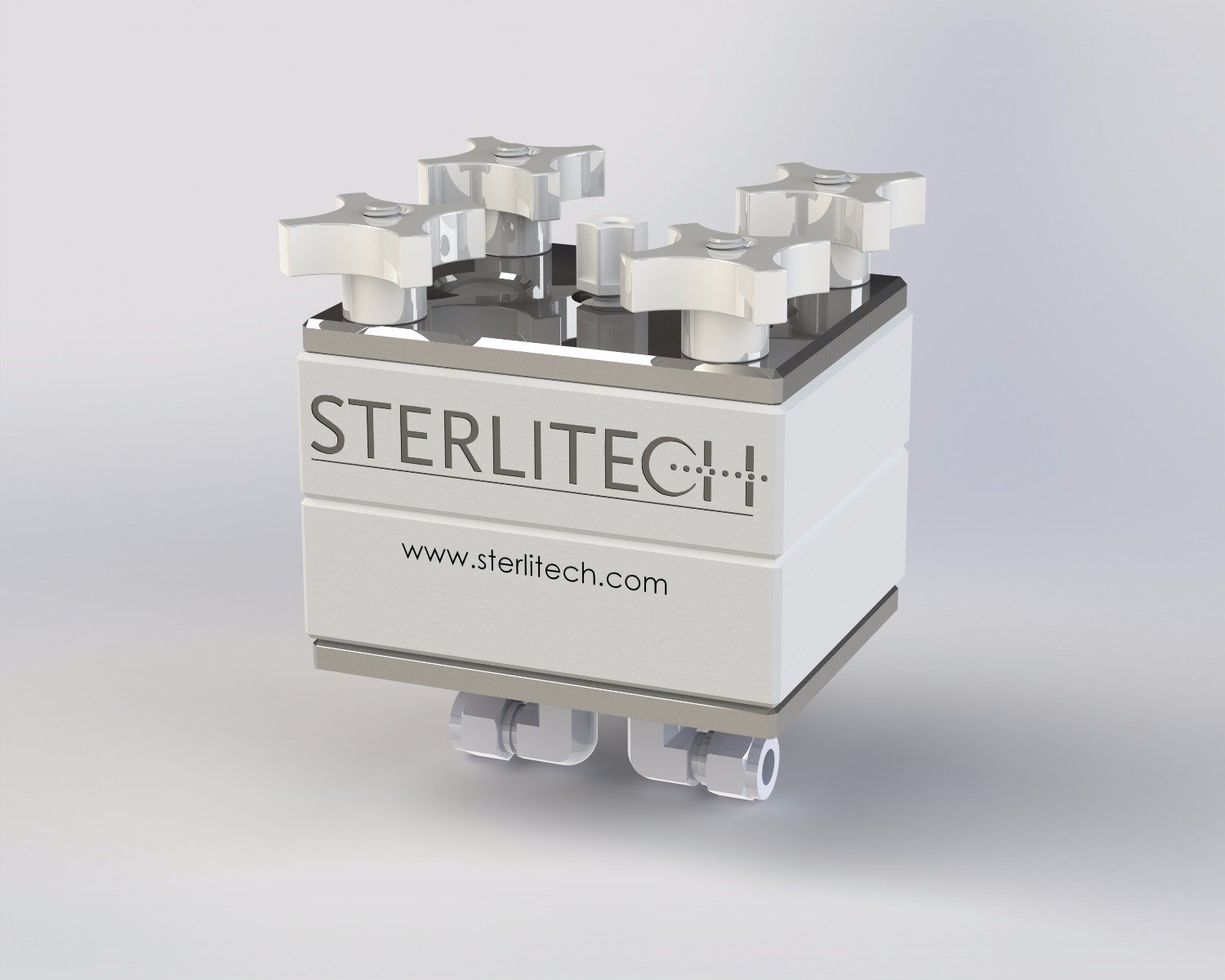

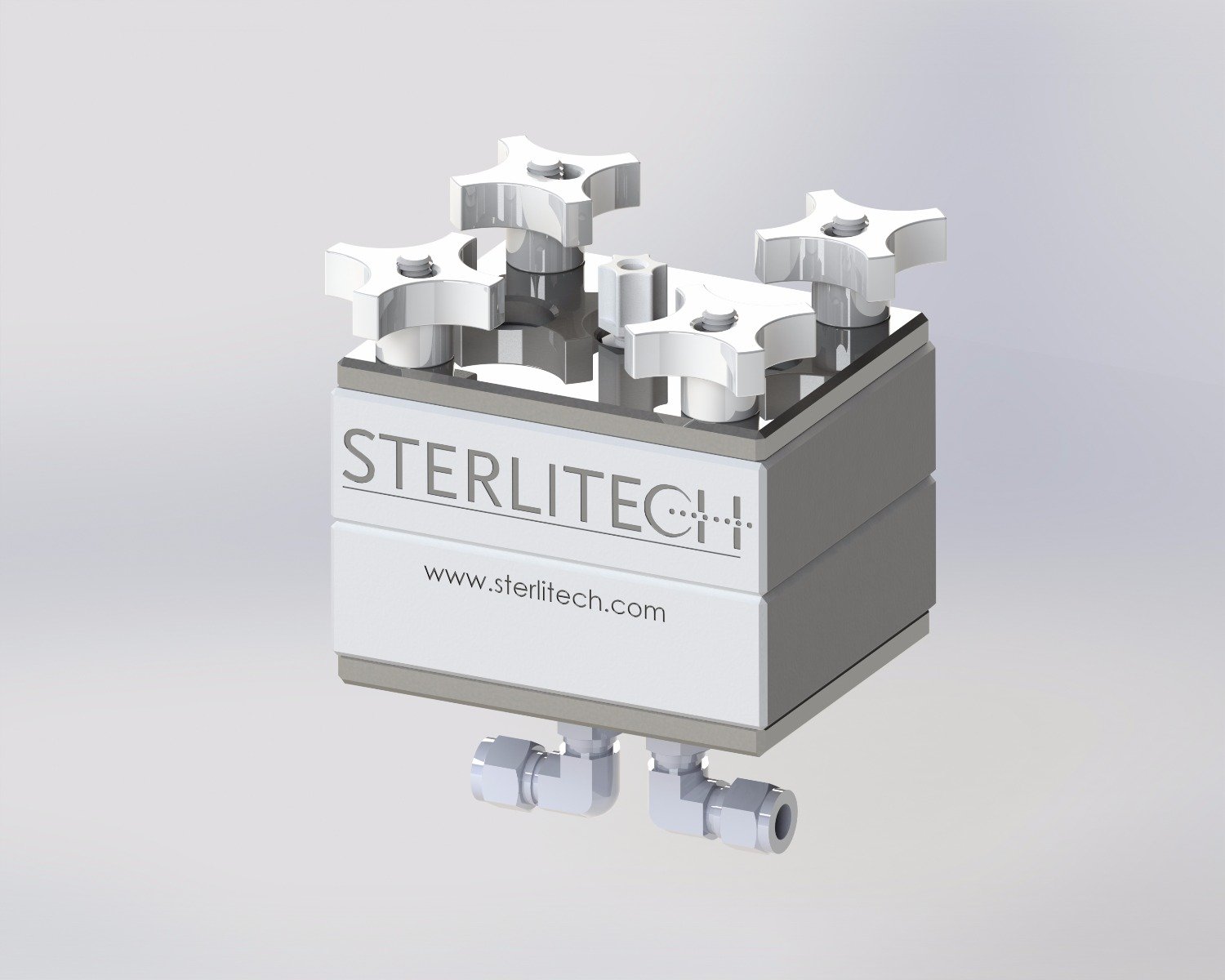

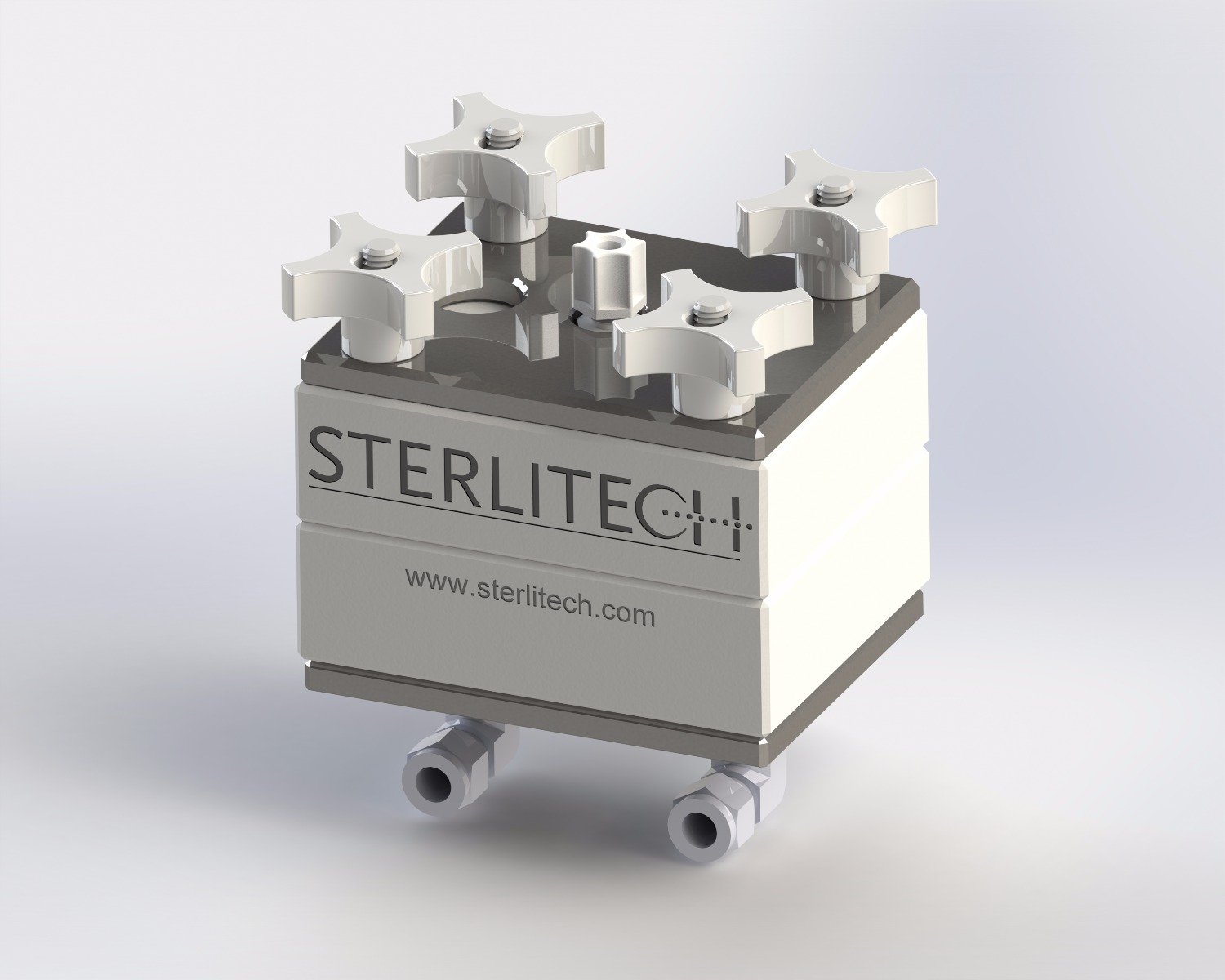

Sepa, Forward Osmosis (FO) Style System, 316 SS

Details

Sepa, Forward Osmosis (FO) Style System, 316 SS

Applications

Forward Osmosis technology is most commonly used for an array of wastewater recycling and water reclamation applications. Areas in which an FO cell may be used include:

- Water reclamation from oil and gas exploration

- Landfill wastewater

- Alternative energy/biogas wastewater

- Medical/dental wastewater

- Membrane bioreactors

- Seawater desalination

- Radioactive wastewater

- Carpet manufacturing wastewater

- Pressure Retarded Osmosis (PRO) to generate electricity

Other uses for Forward Osmosis Cells:

- Pretreatment for Reverse Osmosis procedure

- Concentrating juices (grape juice to wine, tomato paste)

- Pharmaceuticals

- Nutraceuticals

Specifications

Specifications by Material:

| Product Family | Innovator | Explorer | Developer | |||||||||

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Material |

Acetal (Delrin) |

316 Stainless Steel |

Virgin PTFE |

Acrylic |

Acetal (Delrin) |

316 Stainless Steel |

Virgin PTFE |

Acrylic |

Hastelloy™ |

316 Stainless Steel |

Acrylic |

Hastelloy™ |

|

Maximum Bolts Torque Setting (in-lbs) |

60 |

NA |

15 |

45 |

60 |

NA |

15 |

45 |

70 |

NA |

45 |

70 |

|

Maximum Fittings Torque Setting (in-lbs) |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max Pressure |

69 bar |

69 bar |

27.6 bar |

27.6 bar |

69 bar |

69 bar |

27.6 bar |

27.6 bar |

69 bar |

69 bar |

15.2 bar |

69 bar |

|

Max Temperature |

82°C |

150°C |

260°C |

88°C |

82°C |

150°C |

260°C |

88°C |

150°C |

150°C |

88°C |

150°C |

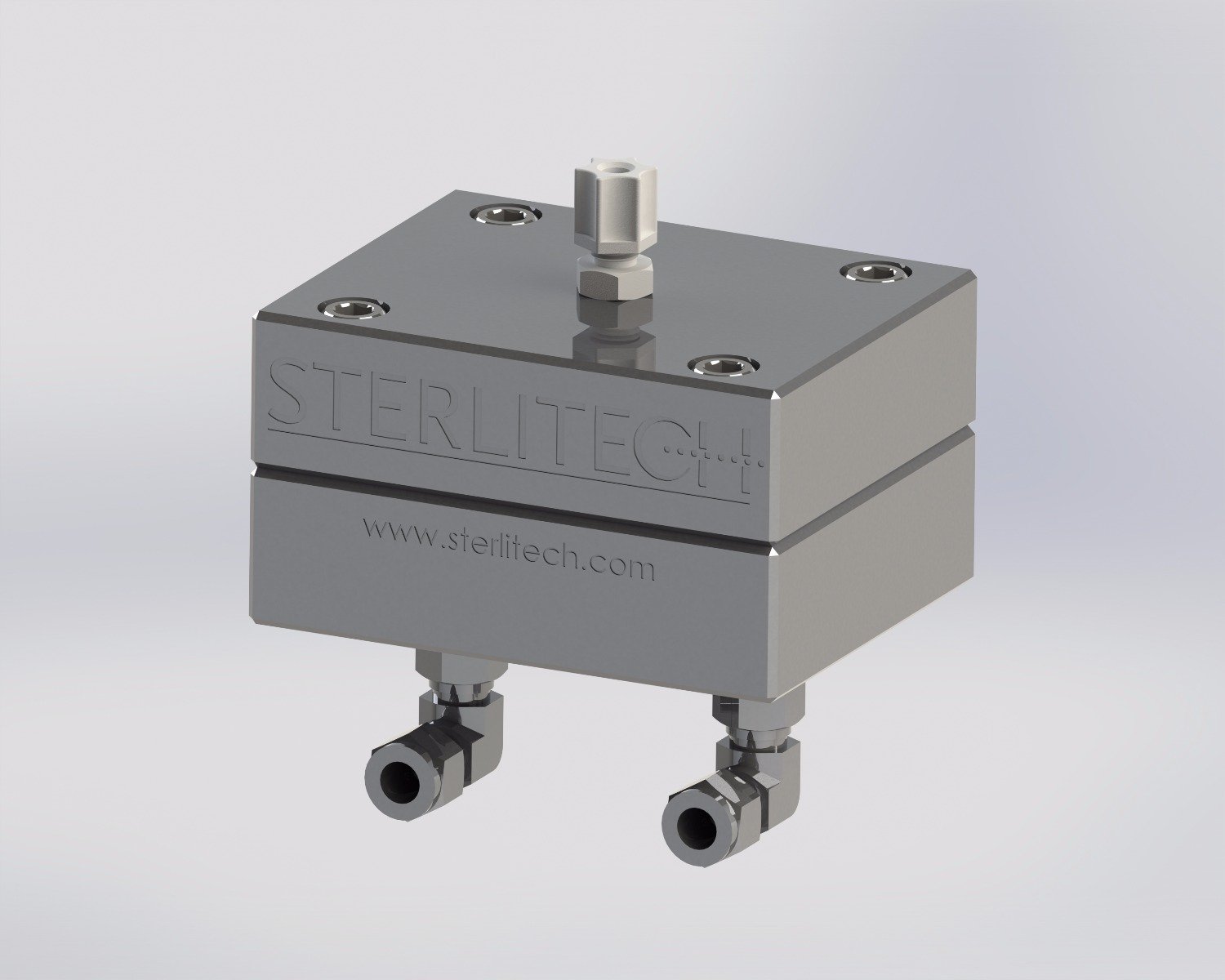

General FO Cell Specifications:

| CF016-FO | CF042-FO | Sepa FO | |

|---|---|---|---|

| Active Membrane Area | 20.6 cm2 (3.2 in2) | 42 cm2 (6.5 in2) | 140 cm2 (22 in2) |

| Hold-Up Vol. | 13 mL (0.44 oz) | 17 mL (0.57 oz) | 70 mL (2.4 oz) |

Connections |

Feed:1/4 in FNPT (base of cell) Draw Solute:1/4 in FNPT (top of cell) |

Feed:1/4 in FNPT (base of cell) Draw Solute:1/4 in FNPT (top of cell) |

Feed:1/4 in FNPT (base of cell) Draw Solute:1/4 in FNPT (top of cell) |

| Outer Dimensions | 12.7 x 10 x 8.3 cm (5 x 4 x 3.25 in) | 12.7 x 10 x 8.3 cm (5 x 4 x 3.25 in) | 16.51 x 21.3 x 5 cm (6.5 x 8.38 x 2.07 in) |

| Active Area Dimensions | 4.52 x 4.52 cm (1.78 x 1.78 in) | 9.207 x 4.572 cm (3.625 x 1.8 in) | 9.7 x 14.7 cm (3.81 x 5.78 in) |

| Slot Depth | 0.23 cm (0.09 in) | 0.23 cm (0.09 in) | 0.19 cm (0.075 in) |

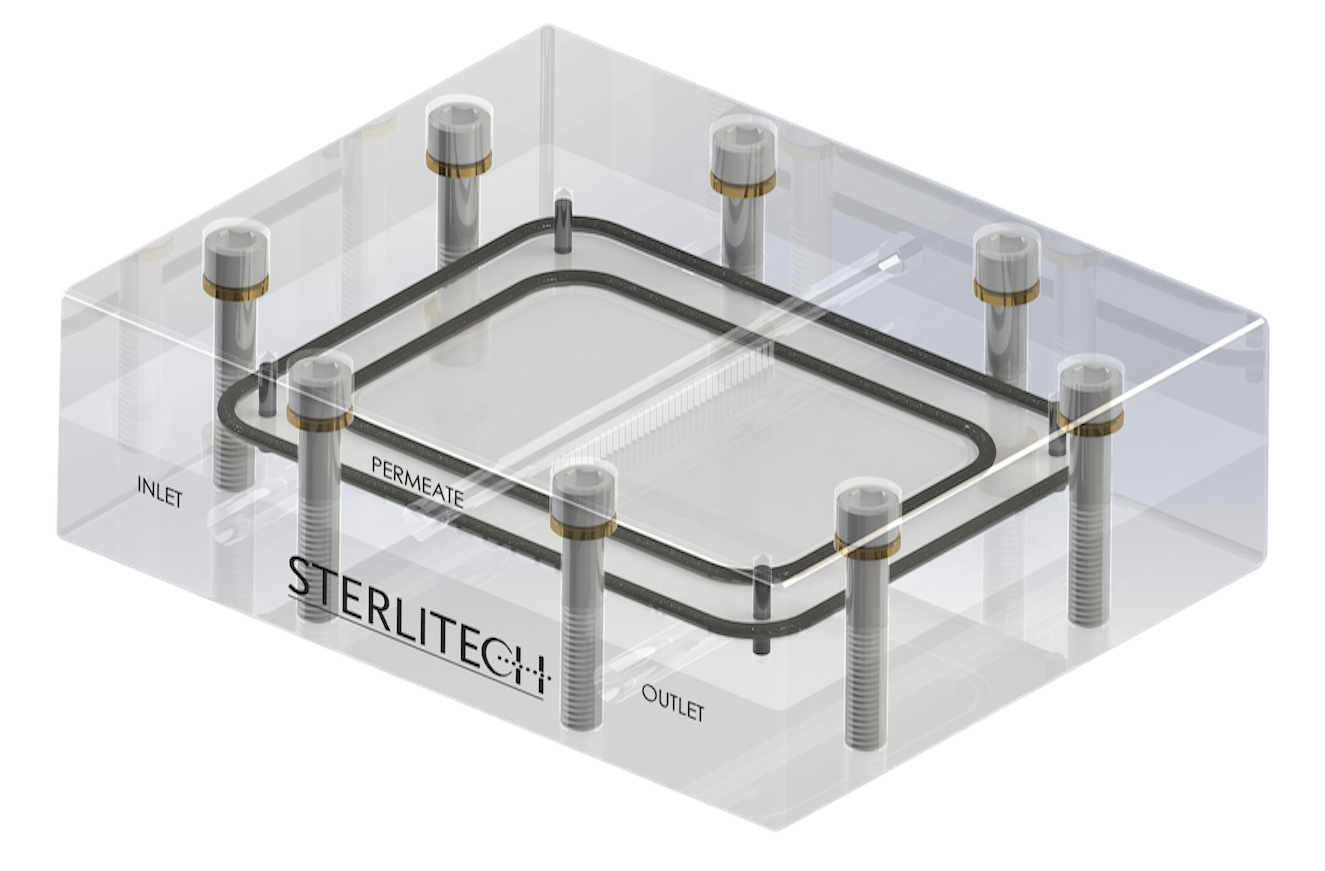

| Below is a animated diagram demonstrating how the Sepa FO cell works: | Forward Osmosis Bench-top Filtration System |

|---|---|

|

|

|

Frequently Asked Questions

Frequently Asked Questions

Q: Why is the flat sheet membrane I'm using measuring a flux value less than the published flux value?

Flow characteristics for a spiral element and flat sheet membrane are significantly different and are really only comparable on a qualitative basis. Variability in the membrane manufacturing process, differences in water composition, test procedures, and test equipment, used in a factory, laboratory, or elsewhere, will impact water flux results.

Q: How do I store used forward osmosis (FO) flat sheet membranes?

Q. How do i store used forward osmosis (FO) flat sheet membranes?

Post use, the membrane should be rinsed with water after testing and stored in clean water if the storage duration will be less than 24 hours. If the membrane is rinsed with water and expected to be stored for longer than 48 hours, it is recommend to use a 1% sodium metabisulfite (SMB, chemical formula Na2S2O5) to prevent bacterial growth from occurring. Periodically inspect the membranes for biological growth. If the preservative solution is cloudy you need to replace it. Renew the preservative solution every month.

Q: How do I install/remove permeate fittings or other plastic NPT fittings?

Sterlitech recommends to install all plastic fittings by hand using PTFE tape. If a plastic NPT or compression fitting starts to leak during operational testing, tighten the fitting carefully until the leaking stops. Excessive tightening may break the fitting or damage other components.

If the fittings is broken and stuck in the cell top, use a spiral flute extractor bit or similar tool to release the portion of the fitting in the cell top. If the cell top becomes cracked from removal efforts, a replacement can be purchased.