Membrane/Process Development

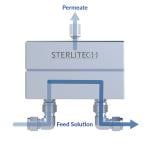

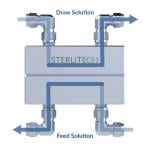

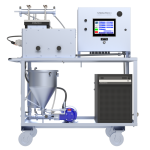

The Membrane and Process Development Product line at Sterlitech includes a wide range of commercially available polymeric flat sheet membranes as well as ceramic membranes, bench-scale cross/tangential flow test cells, and filtration equipment. Ideal for membrane development applications including performance characterization, and comparison studies, it can also be used for feasibilities studies in applied research and small scale processing.

Need help getting started? Visit our MPD Overview page to find outlined steps for a complete MPD setup or watch instructional videos on our MPD Video Channel.

Frequently Asked Questions

Frequently Asked Questions

Q: Do you need a Chemical Compatibility Chart?

We have a Chemical Compatibility Chart that you can use for reference.

Q: What is the recommended flow rate for the CF cells?

Please refer to the following diagram to examine recommended feed flow rates for the crossflow cell you are working with.

Q: Why is the flat sheet membrane I'm using measuring a flux value less than the published flux value?

Flow characteristics for a spiral element and flat sheet membrane are significantly different and are really only comparable on a qualitative basis. Variability in the membrane manufacturing process, differences in water composition, test procedures, and test equipment, used in a factory, laboratory, or elsewhere, will impact water flux results.

Q: What is the recommended flow rate for the CF cells?

lease refer to the following diagram to examine recommended feed flow rates for the crossflow cell you are working with.

Q: What is the application of feed spacer?

Feed spacers are used to mimic the hydrodynamic conditions of large-scale membrane modules by changing the flow regime and creating turbulence inside the feed channel of our membrane test cells.

For more information on feed spacers incorporated into our test cells, please visit here.

Q: What is the thickness of feed spacers (17, 31, 47, and 65 mil diamond spacers)?

The “mil” measurement represents 1/1000th of an inch. Therefore, the thicknesses are 0.017, 0.031, 0.047, 0.065 inches (17, 31, 47, and 65 mil, accordingly).

Q: What is the application of permeate carriers?

Permeate carriers, also known as “permeate water carriers” are aids that are installed between two layers of the flat sheet membranes in a spiral wound element. The main application of this collection layer is to prevent the membrane layers from closing in on each other under high-pressure operations and also facilitate the collection of permeate water.

Q: What is the recommended replacement frequency for the Hydracell pump oil?

Hydracell pump oil needs to be changed after the first 100 hours of operation. Then, pump oil should be changed according to the guidelines described in the pump user manual. For more information on the pump please see user manual.

Q: What is the application of shims?

During high-pressure filtration processes, the membrane sheet inside the cell may deflect outwards into the feed channel. This occurs due to variations in pressure during operation. This movement can cause rubbing against O-rings which can result in abrasion, possibility rupture, in the membrane sheet. Therefore, a piece of material (shim) can also be placed between the membrane layer and the test cell to take up the free space and help to prevent movement.

For more information on shims incorporated into our test cells, please visit here.