Membrane Distillation

Membrane Distillation (MD), a temperature driven membrane separation process, is widely used in desalination, concentration in food industries, acid manufacturing, removing organic and heavy metals, and treating radioactive waste. This process offers advantages such as:

- Low operating temperatures

- Low hydrostatic pressures

- Less susceptibility to fouling

- Ability to use renewable energy or waste heat

Interested in learning how to operate our membrane process equipment? Check out our MPD channel to watch videos now!

| SKU | Product Name | Est Ship | Price | ||

|---|---|---|---|---|---|

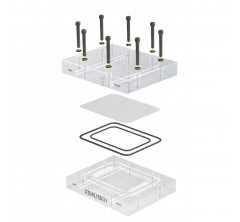

| 1160007 | Sepa Cell, Forward Osmosis & DCMD, Acrylic | 1-2 days | $3,233.62 | |

| 1200675 | DCMD Kit with Chiller and Immersion Heater, 110V, 60Hz, 1Ph | 3-4 weeks | $28,823.64 | |

| 1200678 | DCMD Kit with Chiller and Immersion Heater, 230V, 50Hz, 1Ph | 3-4 weeks | $28,823.64 | |

| 1160071 | Air Gap Membrane Distillation Cell, Acrylic | 1-2 days | $3,866.91 | |

| 1160346 | Sepa Cell, Forward Osmosis, PEEK | Contact Us | $6,465.44 |

Accessory

| SKU | Product Name | Price | ||

|---|---|---|---|---|

| 1160097 | Air Gap Membrane Distillation Conversion Kit | $614.84 | |

| 1160434 | Air Gap Membrane Distillation Conversion Kit for Sepa, Chemical Resistant | $2,200.10 |

Applications

Membrane Distillation (MD) is widely used in separation processes such as:

- Desalination

- Concentration in food industries

- Acid manufacturing

- Removing organic and heavy metals

- Treating radioactive waste

Sterlitech carries membranes specifically for membrane distillation:

- PTFE (Unlaminated, Laminated, and Aspire Laminated)

These membranes vary in terms of pore size, thickness, polymer, which in turn effect permeability, chemical compatibility, and water entry pressure. All are hydrophobic, and have different maximum operating temperatures.

Documentation

Supporting

![]() View the P&ID for the analog system configured with DCMD Cell

View the P&ID for the analog system configured with DCMD Cell

White Paper on Membrane Distillation: Recent Developments and Breakthrough Products