Silver Membranes

Silver metal membrane filters are used in a variety of filtration applications, and their ability to withstand extreme chemical and thermal stress makes them ideal laboratory filtration equipment for applications involving aggressive fluids and/or high temperatures.

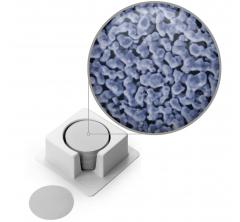

Silver metal filter membranes are pure metallic silver (99.97% pure silver) and are available with particle retention ratings of 0.2 to 5.0 microns. These silver metal membrane disc filters and sheets are specified in a National Institute for Occupational Safety and Health (NIOSH) standard for the analysis of crystalline and amorphous silica, lead sulfide, boron carbide, and chrysotile asbestos. Sterlitech's silver metal membranes can be used as the collection media and subsequent x-ray diffraction substrate for quantifying unknown minerals and compounds.

Start with a custom silver membrane sample pack here.

We provide the filters and technical support to help you take your breakthrough product from an idea to a prototype, to commercial scale.

Silver Membrane Filter Applications

Sterlitech™ Silver Membranes can be used for a wide variety of industrial hygiene, OSHA and laboratory applications.

Analytical

- X-ray diffraction (XRD); silver metal membranes make excellent substrates for XRD analysis - silver purity 99.97% -- smooth surface, grayish-white color; highly reflective surface; absolute surface retention; low background noise; distinct diffraction peaks.

- Scanning Electron Microscopy (EM); smooth; electrically conductive; extremely thin membrane 50 µm; easy sample preparation.

Gas

- Air-borne contaminants - National Institute for Occupational Safety and Health (NIOSH) - used for industrial hygiene in foundries, glass plants, quarries, mines, ceramic manufacturing - Methods using 0.45 µm, 25 mm:

- Respirable Combustible Dust (RCD) sampling and analysis - 0.8 µm, 25 mm, mines - measurement of diesel particulate matter, evaporated hydraulic fluids, fuel oils, and compressed air lubricants by weighing and ashing.

- Dopant gases for semiconductor manufacturing.

- Steam, or air sterilization, autoclavable

- Venting, high temperatures

Liquid

- Clarification (3.0-5.0 µm); Polishing (1.2 µm); Sterilization (0.2-0.8 µm)

- Intrinsically Bacteriostatic - Silver does not allow the growth of bacteria and other microorganisms.

- High-Performance Liquid Chromatography (HPLC) for a clearer; steadier baseline - may rule out interference from other sources of HPLC solvents (0.2, 0.45, and 0.8 &micor;m); tolerates high temperatures; gases and aggressive liquids -- Tetrahydrofuran (THF)

Viscous Fluid

- Organic Carbon, inorganic, and suspended-sediment water - 0.45 µm, 47 mm, used by U.S. Geological Survey (USGS)

- Lubrication oils for servomechanisms and precision instruments

- Direct-line Applications with a Sprayer

- High-purity fluids in semiconductor applications

Other Industrial

- Chlorine Monitoring - Pulp and Paper Industry, disinfection; removal of tin and zinc in iron; chlorinating hydrocarbons; manufacturing synthetic rubber, plastics, pesticides, refrigerants; treating water and sewage

- Electronics Industry - filter coolants, cleaning fluids, sterile air

- Aircraft/Missile Fuels; critical fluids - resists alcohols, fuels, hydrocarbons, polyaromatic hydrocarbons (PAH), oils, alkalies, ethers

- OSHA - coal tar pitch volatiles, 0.8 µm, 47 mm and 37 mm

- Cold Sterilization (beverages, beer) - absolute particle-retention due to precise pore size

- Soil and clay analysis

- Fly Ash Sampling; Energy Research and Development Agency (ERDA)

- Bacteria Sampling

Silver Membrane Filter Specifications

General

Coefficient of Thermal Expansion: 18.8 x 106 per °C

Thickness: 50 µm (1.97 mil)

Sterilization: Air, Autoclave, Steam

Resistivity: 1.59 x 10-8 Ωm at 20 °C (68 °F)

Specific Heat: 0.448 cal/g at 20 °C (68 °F)

Performance by Pore Size

| Pore Sizea | H2O Flow Rateb | Air Flow Ratec | Bubble Pointd | Max. Operating Temp.e |

|---|---|---|---|---|

| 0.2 µm | 17 | 0.35 | 13 | 204°C (400°F) |

| 0.45 µm | 40 | 0.67 | 9 | 204°C (400°F) |

| 0.8 µm | 340 | 1.4 | 7 | 204°C (400°F) |

| 1.2 µm | 460 | 2.0 | 5 | 204°C (400°F) |

| 3 µm | 690 | 2.9 | 3 | 427°C (800°F) |

| 5 µm | 870 | 5.2 | 2 | 427°C (800°F) |

a. Particle retention verified by bubble point pressure

b. Measured in mL/min/cm2 w/pre-filtered H2O at ΔP of 10 psid (0.7 bar); pre-wetted w/methanol

c. Initial flow rates measured in L/min/cm2 w/pre-filtered air at 10 psi (0.7 kg/cm2)

d. Measured using methanol

e. Silver membranes provide excellent filtration performance at temperatures up to 427°C (800°F)

Documentation

Working with Silver Membranes Video

Frequently Asked Questions

Frequently Asked Questions

Q: What is the shelf life of the silver membrane filters?

A. There is no predetermined shelf life for the silver membrane. The filters should be stored sealed in the original packaging until needed. Over time, silver compounds may form on the surface of the membrane. Any resulting surface discoloration is essentially cosmetic and does not affect filter performance.

Q: What is the difference between hydrophilic and hydrophobic membrane filters?

The pores of microporous membrane filters act as small capillaries. When hydrophilic membranes come into contact with water, capillary action associated with surface tension forces causes the water to spontaneously enter and fill the pores. In this manner, the membranes are easily wetted and allow the bulk flow of water through the pores. Once wetted, hydrophilic membranes will not allow the bulk flow of air or other gasses, unless they are applied at pressures greater than the membrane’s bubble point.

Hydrophilic membrane filters are typically used with water and aqueous solutions. They can also be used with compatible non-aqueous fluids. Hydrophilic membrane filters are typically not used for air, gas or vent filtration since the filters would block flow if inadvertently wetted, by condensation for example.

When hydrophobic membranes come into contact with water, surface tension forces act to repel the water from the pores. Water will not enter the pores and the membranes will act as a barrier to water flow, unless the water is applied at pressures greater than the membrane’s water entry pressure. Low surface tension fluids, such as alcohols, can spontaneously enter and fill the pores of hydrophobic membranes. Once all the air in the pores is displaced, there are no longer any surface tension forces and water can easily enter the pores, displace the low surface tension fluid, and pass through the membrane. The membrane will then allow bulk flow of water for as long as the pore remain water filled. If the membrane is allowed to dry (i.e. air enters the pores), then it must be pre-wet with a low surface tension fluid again prior to use with water.

Hydrophobic membrane filters are typically used with compatible non-aqueous fluids. They are also commonly used as air, gas, or vent filters. Hydrophobic membrane filters are sometimes used with water or aqueous solutions; and, in these applications, they must first be prewet with a low surface tension, water miscible fluid prior to use.

Q: What does it mean if my silver membrane filter is slightly discolored?

Q. What if my membrane is slightly discolored?

A. Although the silver metal membrane is 99.97% pure silver, the formation of extraneous compounds is possible over time. For example, silver can become tarnished, especially when the environment contains certain emissions as described below. To minimize contamination of the membrane, leave it in sealed packs. Silver compounds may form on the surface which are primarily cosmetic imperfections and do not affect the pore structure or membrane filtration performance. Examples of colored compounds that can form on the surface of the silver metal membrane are:

• Ag2S (black)

• Agl (yellow)

• Ag3PO4 (yellow)

• Ag2CrO4 (dark red)

• AgCl (dark brown)

• Ag2O (dark brown)

• AgBr (light yellow)

The most common compounds that form on the silver metal membrane are Ag2S and AgCl. AgCl is a photosensitive salt that can be removed by flushing the membrane with an ammonia solution. Typically, just a brief soak or dip in the ammonia solution will dissolve AgCl. Ag2S is a very stable compound and is very difficult to remove from the membrane without altering the structure. A flush with methyl or ethyl alcohol can be used to remove some of the other compounds.

These compounds should not be confused with the natural grayish white appearance of the silver metal membrane surface. This appearance is due to the microporous structure of the media which reflects light in a manner different than polished silver. The slight difference in color between the two sides of the membrane is due to the manufacturing process and is most noticeable on 3 and 5 micron pores sizes.

Q: What NIOSH Standards are Silver Membranes specified for?

Q. What NIOSH Standards are Silver Membranes specified for?

A. National Institute for Occupational Safety and Health (NIOSH) - used for industrial hygiene in foundries, glass plants, quarries, mines, ceramic manufacturing - Methods using 0.45 µm, 25 mm:

N6011 (Bromine & Chlorine) - http://www.cdc.gov/niosh/docs/2003-154/pdfs/6011.pdf

N7500 (Silica, Crystalline) - http://www.cdc.gov/niosh/docs/2003-154/pdfs/7500.pdf

N7501 (Silica, Amorphous) - http://www.cdc.gov/niosh/docs/2003-154/pdfs/7501.pdf

N7504 (Vanadium Oxide) - http://www.cdc.gov/niosh/docs/2003-154/pdfs/7504.pdf

N7505 (Lead Sulfide) - http://www.cdc.gov/niosh/docs/2003-154/pdfs/7505.pdf

N7506 (Boron Carbide) - http://www.cdc.gov/niosh/docs/2003-154/pdfs/7506.pdf

N9000 (Asbestos, Crysotile) - http://www.cdc.gov/niosh/docs/2003-154/pdfs/9000.pdf

Q: Can silver membrane filters be cleaned?

Q. Can silver metal membranes be cleaned?

A. Sterlitech™ Silver Membranes: Cleaning Guidelines

Sterlitech’s Silver Metal Membrane Filters can be cleaned and reused repeatedly. The membranes should be cleaned immediately after each use, and handled carefully to avoid membrane punctures and tears. Various cleaning procedures can be used, depending on the nature, type, and degree of contamination. There are four effective cleaning methods outlined below, that can be used to clean Sterlitech’s silver metal membrane filters.

Chemical Cleaning

Immerse in a strong alkaline solution, a solvent, or an acid. Do not immerse in nitric acid, sulfuric acid, or cyanide solutions.

Ignition Cleaning

Place the silver metal membrane filter in a laboratory muffle furnace for approximately ½ hour to effectively remove organic contaminants from the membrane. Do not exceed the following temperatures.

| Retention Rating (microns) | Maximum Temperature | |

| °C | °F | |

| 5.0 | 550 | 1020 |

| 3.0 | 400 | 750 |

| 1.2 | 350 | 660 |

| 0.8 | 300 | 570 |

| 0.45 | 300 | 570 |

| 0.2 | 250 | 480 |

Combination Cleaning

A combination of chemical and ignition cleaning may be the best method to completely regenerate the membrane. Immerse in a 10 percent concentration of hydrofluoric acid for ten minutes, followed by ignition cleaning in a muffle furnace, following the guidelines given above. This can allow for reuse of membrane up to 10 times.

Ultrasonic Cleaning

Low intensity ultrasonics can be used to clean the silver metal membrane. The cleaning intensity and time will depend on the degree and type of contamination encountered. Do not use high intensity ultrasonics.

Q: What are the specifications for the silver metal membranes?

Q. What are the specifications for the silver metal membranes?

A. Excellent Chemical and Thermal Properties: Sterlitech™ Silver Metal Membranes have the chemical inertness and high thermal stability of pure silver. The membranes resist alcohols, fuels, and other hydrocarbons including halogenated hydrocarbons, natural and synthetic oils, alkalies, cryogenic fluids, photo-resists, ethers, propellants, oxidizers, esters, most organics and acids making them ideal for industrial hygiene tests. Silver Metal Membranes provide excellent filtration performance at temperatures up to 427°C (800°F). The membranes can be autoclaved, steam or hot air sterilized a number of times without losing effectiveness.

Molecularly Bonded Filter Media: Sterlitech™ Silver Metal Membranes are formed by a reaction bonding mechanism that transforms a suspension of amorphous silver into a strong, homogeneous crystalline network of porous silver. They are the only molecularly bonded metal membranes available; all other metal filters are sintered.

Non-Absorptive - Non-Adsorptive: Adsorption and absorption by Sterlitech™ Silver Metal Membranes are virtually nonexistent due to the chemical and biological inertness of pure silver, and the smooth, regular shape of the silver media.

Intrinsic Bacteriostatic Nature: The intrinsic bacteriostatic property of silver does not allow the growth of bacteria and other microorganisms.

Surface Retention: The flat, smooth surface of Silver Metal Membranes allows for true surface capture. Performance tests show that the absolute particle retention of Sterlitech™ Silver Metal Membranes is achieved by mechanical sieving in the filter structure. Thus, particle retention by the filter membrane is independent of variable molecular forces, such as adsorption.

Economical and Reusable: Sterlitech™ Silver Metal Membranes are usually more economical than disposable filters because the Silver Metal Membranes can be used several times after chemical or ignition cleaning. In addition, the basic price of these membranes is not as high as one might expect, the amount of silver is relatively small because the membrane is approximately 60 percent open space.

No Fiber Release - No Media Migration: Sterlitech™ Silver Metal Membranes are fiber-free and feature virtually no media migration because they are strong, uniform, porous monolithic structures consisting of metallic crystals. Conventional polymeric membranes and other lab filters often shed fibers and other parts of the media so the filter itself contaminates the filtrate.

High Flow Rates: Sterlitech™ Silver Metal Membranes are extremely thin (50 µm or 0.002 inch). This feature, plus a high porosity of 60 percent open area, provides exceptionally high flow rates.

Q: What are the advantages of Silver membrane filters?

Q. What are the advantages of silver metal membranes over conventional membranes?

A. Sterlitech™ Silver Metal Membranes are 99.97% pure, thus unique in their ability to withstand extreme chemical and thermal stress, making them ideal for applications involving aggressive fluids and/or high temperatures. In addition, the purity of the membranes enables users to easily exclude and account for the few chemicals that react with silver, thus making test results and filtering operations more precise than available through traditional membranes.

Q: What are the Silver Membrane lead times?

Q. What are the Silver Membrane lead times?

A. We carry most diameters and pore sizes of Sterlitech™ Silver Metal Membranes in stock and will generally ship within one or two days.

Q: Can silver membrane filters be sterilized with ethylene oxide (EtO)?

Q: Can silver membrane filters be sterilized with ethylene oxide (EtO)?

A: EtO sterilization is not recommended for silver membrane filters. There is a possibility that residual acetylene in the EtO can produce explosive silver acetylide capable of detonating the EtO vapor.

Q: Can you recycle my used silver membrane filters?

We can not recyle your filters. However, we have used Sims Recyling for many years (https://www.simslifecycle.com/) to recycle our scrap silver.

Q: What is the maximum temperature for the different filter membranes?

Q. What is the maximum temperature for the different filter membranes?

A. The maximum operating temperatures for Sterlitech filter membranes are listed below.

- Sterlitech Silver Metal - 427°C

- Sterlitech Ceramic - 350°C

- Sterlitech Polycarbonate Track Etch - 140°C

- Sterlitech Polyester - 140°C

- Sterlitech Nitrocellulose (MCE) - 130°C

- Sterlitech Nylon - 180°C

- Sterlitech Polyethersulfone (PES) - *130°C

- Sterlitech Polypropylene - 82°C

- Sterlitech Cellulose Acetate - 135°C

- Sterlitech PTFE (Laminated) - 130°C

- Sterlitech PTFE (Unlaminated) - 260°C

- Sterlitech PVC Data not available

*5.0um and 8.0um - max temp is 180°C

Q: What is the difference between nominal and absolute pore size ratings?

Q. What is the difference between nominal and absolute pore size ratings?

Nominal pore size ratings are provided as a general indication of filter retention. It is understood that some quantity of particles greater than, and equal to, the nominal pore size ratings will pass through the filters into the filtrate. Some manufactures may associate nominal pore size ratings with percentage filtration efficiencies. Nominal pore size ratings vary from manufacturer to manufacturer and, consequently, are not necessarily equivalent. Filters from different manufactures with similar nominal pore size ratings may not actually exhibit similar retention characteristics.

Absolute pore size ratings are typically based on retention studies performed using challenge suspensions of standard microorganism cultures or particles of known size. Absolute pore size ratings represent the size of the smallest microorganisms or particles completely retained during these studies. Absolute pore size ratings are almost always correlated to bubble point specifications that are used for quality control during membrane manufacturing. For the most part, absolute pore size ratings, especially those based on microbial retention, are comparable from manufacturer to manufacturer. There is more uncertainty for absolute pore size ratings based on particle retention studies, especially for pore size ratings <0.2µm, since there are no standard methods for these studies.

Regardless of pore size ratings, it is important to understand that application conditions do influence particle retention. Even filters with absolute pore size ratings can be operated in conditions that will allow unexpectedly sized particles to pass.

Q: What is the difference between pore size and porosity?

The pore size refers to the diameter of the individual pores in a membrane filter. Pore size is typically specified in micrometers (µm). Most membranes and filter media actually contain a distribution of pore sizes. Nominal pore size ratings typically refer to the predominant pore size of a filtration media; pores larger and smaller than the nominal rating may be present. Absolute pore size ratings typically refer to the largest pore size of a membrane and it is expected that all pores will be equal to or smaller than the absolute rating.

For the polycarbonate track-etch (PCTE) and polyester track-etch (PETE) membrane filters, porosity is the percent of the total surface area occupied by the pores; it typically ranges from <1% to 16%. For the other membrane filters, porosity is the percent of the total volume occupied by the pores; it typically ranges from 40 to 80%.

Q: How do I determine if my filter is compatible with my application?

You can find the Sterlitech compatibility guide. It is important to realize that application conditions, such as operating temperature, affect compatibility. Please contact us at [email protected] if you need assistance.

Q: What is a bubble point and how is it determined?

The bubble point is the minimum amount of pressure required to push air bubbles through the largest pore of a wet membrane. The bubble point is inversely proportional to the pore diameter, as the pore diameter decreases the bubble point increases and vice versa.

Retention efficiency of membrane filters can be directly measured by challenging the filters with suspensions of standard microorganism cultures or particles of known size. Unfortunately, such efficiency testing is necessarily destructive. However, since retention characteristics are dependent on pore size, it is possible to correlate destructive challenge testing results to non-destructive membrane bubble point tests. In this manner, the relationship between membrane pore size and membrane bubble point is empirically determined. Typically, a minimum bubble point can be determined and specified for a particular pore size rating. The bubble point specification is then used for quality control during membrane manufacture. The bubble point can also be used by the consumer as a nondestructive test to verify membrane integrity before and/or after use.

Q: What is the difference between a depth filter and membrane filter?

Depth filters are constructed with relatively thick filtration media and typically have nominal pore size ratings >1µm. Due to their large void volume, they capture significant amounts of particulate within their pore structure.

Membrane filters are typically composed of polymers that have been chemically processed, resulting in highly porous thin films with microscopic pore structures. Membrane filters typically have absolute pore size ratings <1µm, with some exceptions. Because of their very fine pore structure, membrane filters tend to trap the majority of particles on the surface. However, smaller particles with diameters near or below the pore size rating can be captured within the membrane or pass through the membrane.

Q: How can I tell the difference between the separator papers and the membrane filters?

To ensure ease of use, the membrane filters as stacked in their packaging are interleafed with layers of separator paper. In most cases, the membrane filters will be white in color except for the track-etch membranes which are colorless and translucent. In some special cases, the membranes will be dyed dark grey to black in appearance. In all cases, the separator paper will be a different color than the membrane and is usually not white. Please contact us at [email protected] if you need assistance.