PETE (Polyester) Membranes

Our solvent resistant, hydrophilic polyester track etch (PETE) membranes and drain discs are made from a thin, translucent, microporous, polyester film.

We provide the filters and technical support to help you take your breakthrough product from an idea to a prototype, to commercial scale.

Frequently Asked Questions

Frequently Asked Questions

Q: What is the difference between hydrophilic and hydrophobic membrane filters?

The pores of microporous membrane filters act as small capillaries. When hydrophilic membranes come into contact with water, capillary action associated with surface tension forces causes the water to spontaneously enter and fill the pores. In this manner, the membranes are easily wetted and allow the bulk flow of water through the pores. Once wetted, hydrophilic membranes will not allow the bulk flow of air or other gasses, unless they are applied at pressures greater than the membrane’s bubble point.

Hydrophilic membrane filters are typically used with water and aqueous solutions. They can also be used with compatible non-aqueous fluids. Hydrophilic membrane filters are typically not used for air, gas or vent filtration since the filters would block flow if inadvertently wetted, by condensation for example.

When hydrophobic membranes come into contact with water, surface tension forces act to repel the water from the pores. Water will not enter the pores and the membranes will act as a barrier to water flow, unless the water is applied at pressures greater than the membrane’s water entry pressure. Low surface tension fluids, such as alcohols, can spontaneously enter and fill the pores of hydrophobic membranes. Once all the air in the pores is displaced, there are no longer any surface tension forces and water can easily enter the pores, displace the low surface tension fluid, and pass through the membrane. The membrane will then allow bulk flow of water for as long as the pore remain water filled. If the membrane is allowed to dry (i.e. air enters the pores), then it must be pre-wet with a low surface tension fluid again prior to use with water.

Hydrophobic membrane filters are typically used with compatible non-aqueous fluids. They are also commonly used as air, gas, or vent filters. Hydrophobic membrane filters are sometimes used with water or aqueous solutions; and, in these applications, they must first be prewet with a low surface tension, water miscible fluid prior to use.

Q: What are the advantages of PETE membrane filters?

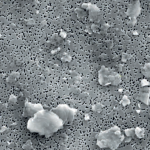

Sterlitech polyester track-etch (PETE) membrane filters are made from integral polyethylene terephthalate films. This construction ensures no potential for sloughing or particle shedding and broad chemical compatibility. Inherently hydrophilic, the filters do not require PVP treatment. They exhibit virtually the lowest extractables and adsorption characteristics for any polymeric membrane filters ensuring filtrate purity. Particles are retained on a flat, glass-like smooth surface with an even distribution in a single plane, facilitating microscopic and SEM analyses of the retentate. The PETE membrane filters have superior resistance to high operating pressures when used in appropriate holders.

Q: What kind of polyester is used to make your polyester track etch (PETE) membranes?

The Sterlitech polyester track-etch (PETE) membranes are made of polyethylene terephthalate.

Q: Will Sterlitech polyester tract-etch (PETE) or polycarbonate track-etch (PCTE) membrane filters keep liquid behind the filter while allowing gases pass through?

Hydrophobic membrane filters are necessary for applications where the membrane is used to retain liquid water while allowing gases to pass through. Hydrophobic PCTE membranes typically have insufficient water entry pressures for these applications and will allow liquid water to pass at pressures lower than required. Hydrophobic PTFE and PETE membrane filters have the highest water entry pressures for membrane filters and are commonly used for these applications.

Q: Can I measure the pore size of polyester track-etch (PETE) membrane filters with a SEM?

It is possible to estimate the pore diameter of polyester track-etch (PETE) membranes from SEM images. In fact, this is how the pore size is characterized during manufacturing for most of the track-etch membranes. However, it is important to understand that there are calibration and performance variations between different SEMs. There is a good likelihood that a user’s results will not correlate to the manufacturing results that were used to characterize the membrane.

Q: What is the difference between nominal and absolute pore size ratings?

Q. What is the difference between nominal and absolute pore size ratings?

Nominal pore size ratings are provided as a general indication of filter retention. It is understood that some quantity of particles greater than, and equal to, the nominal pore size ratings will pass through the filters into the filtrate. Some manufactures may associate nominal pore size ratings with percentage filtration efficiencies. Nominal pore size ratings vary from manufacturer to manufacturer and, consequently, are not necessarily equivalent. Filters from different manufactures with similar nominal pore size ratings may not actually exhibit similar retention characteristics.

Absolute pore size ratings are typically based on retention studies performed using challenge suspensions of standard microorganism cultures or particles of known size. Absolute pore size ratings represent the size of the smallest microorganisms or particles completely retained during these studies. Absolute pore size ratings are almost always correlated to bubble point specifications that are used for quality control during membrane manufacturing. For the most part, absolute pore size ratings, especially those based on microbial retention, are comparable from manufacturer to manufacturer. There is more uncertainty for absolute pore size ratings based on particle retention studies, especially for pore size ratings <0.2µm, since there are no standard methods for these studies.

Regardless of pore size ratings, it is important to understand that application conditions do influence particle retention. Even filters with absolute pore size ratings can be operated in conditions that will allow unexpectedly sized particles to pass.

Q: What is the difference between pore size and porosity?

The pore size refers to the diameter of the individual pores in a membrane filter. Pore size is typically specified in micrometers (µm). Most membranes and filter media actually contain a distribution of pore sizes. Nominal pore size ratings typically refer to the predominant pore size of a filtration media; pores larger and smaller than the nominal rating may be present. Absolute pore size ratings typically refer to the largest pore size of a membrane and it is expected that all pores will be equal to or smaller than the absolute rating.

For the polycarbonate track-etch (PCTE) and polyester track-etch (PETE) membrane filters, porosity is the percent of the total surface area occupied by the pores; it typically ranges from <1% to 16%. For the other membrane filters, porosity is the percent of the total volume occupied by the pores; it typically ranges from 40 to 80%.

Q: How do I determine if my filter is compatible with my application?

You can find the Sterlitech compatibility guide. It is important to realize that application conditions, such as operating temperature, affect compatibility. Please contact us at [email protected] if you need assistance.

Q: What is a bubble point and how is it determined?

The bubble point is the minimum amount of pressure required to push air bubbles through the largest pore of a wet membrane. The bubble point is inversely proportional to the pore diameter, as the pore diameter decreases the bubble point increases and vice versa.

Retention efficiency of membrane filters can be directly measured by challenging the filters with suspensions of standard microorganism cultures or particles of known size. Unfortunately, such efficiency testing is necessarily destructive. However, since retention characteristics are dependent on pore size, it is possible to correlate destructive challenge testing results to non-destructive membrane bubble point tests. In this manner, the relationship between membrane pore size and membrane bubble point is empirically determined. Typically, a minimum bubble point can be determined and specified for a particular pore size rating. The bubble point specification is then used for quality control during membrane manufacture. The bubble point can also be used by the consumer as a nondestructive test to verify membrane integrity before and/or after use.

Q: What is the difference between a depth filter and membrane filter?

Depth filters are constructed with relatively thick filtration media and typically have nominal pore size ratings >1µm. Due to their large void volume, they capture significant amounts of particulate within their pore structure.

Membrane filters are typically composed of polymers that have been chemically processed, resulting in highly porous thin films with microscopic pore structures. Membrane filters typically have absolute pore size ratings <1µm, with some exceptions. Because of their very fine pore structure, membrane filters tend to trap the majority of particles on the surface. However, smaller particles with diameters near or below the pore size rating can be captured within the membrane or pass through the membrane.

Q: How can I tell the difference between the separator papers and the membrane filters?

To ensure ease of use, the membrane filters as stacked in their packaging are interleafed with layers of separator paper. In most cases, the membrane filters will be white in color except for the track-etch membranes which are colorless and translucent. In some special cases, the membranes will be dyed dark grey to black in appearance. In all cases, the separator paper will be a different color than the membrane and is usually not white. Please contact us at [email protected] if you need assistance.