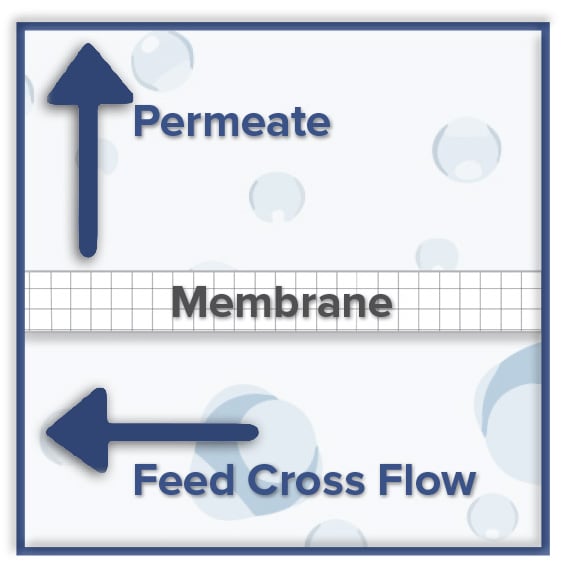

Q: What is Cross Flow Velocity?

A: Cross flow velocity (CFV) is the linear velocity of the flow tangential to the membrane surface and is reported in [m/sec] or [ft/sec]. CFV affects the hydrodynamic conditions in the cell, and as a result affects the fouling rate and formation of concentration polarization at membrane surface and is calculated by dividing the volumetric flow rate [lpm or gpm] in the flow channel by the cross sectional area [m2 or ft2] of the flow channel.

Q: How is CFV calculated in Sterlitech’s bench-scale test cells?

A: Example: Calculate CFV in the CF042 cell

- Flow channel cross sectional area: Channel depth x Channel width* = 0.23 x 3.92 cm

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)