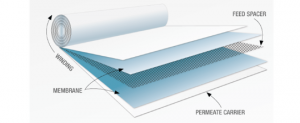

Spiral wound membrane elements generally offer the best combination of filtration area, flux, and compactness of any cross-flow filtration configuration. But how are they made? To help show the answer to everyone, the Science Channel visited Synder Filtration’s Headquarters in California to film a special segment on membrane filtration. The segment will air during the popular show How It’s Made, on April 24, 2014, at 9 PM Eastern Time (6 PM Pacific Time). About Synder Filtration: First established in 1989, Synder Filtration has grown into an international supplier of high quality membrane technology. Emphasizing customer service, technical expertise, and reliable products, Synder Filtration uses their membrane technology to solve industrial and enviro

Monthly Archives: April 2014

- Tuesday, April 22, 2014

- Friday, April 11, 2014

Toray is discontinuing the production of its UTC-80E reverse osmosis membranes. These membranes are being replaced in Sterlitech's line-up by the new UTC-82E membranes, which share the specifications of the UTC-80E. We've listed their specifications below to aid comparison with other flat sheet membranes:

Designation Polymer Molecular Weight Cut-off (MWCO) Rej-Size pH Range @ 25 °C Typical Flux/psi GFD*@PSI 80E/82E Polyamide 0 MWCO 99.8 - Thursday, April 10, 2014

The GM line of ultrafiltration membranes from GE Osmonics is being discontinued. At this time, these membranes do not have any direct replacements, although the GK series, also from GE Osmonics, is used in many of the same applications. We've listed their specifications below to aid comparison with other flat sheet membranes:

Designation Polymer Molecular Weight Cut-off (MWCO) Rej-Size pH Range @ 25 °C Typical Flux/psi GFD*@PSI GM Thin Film 8000 MWCO 8K-PEG - Tuesday, April 01, 2014

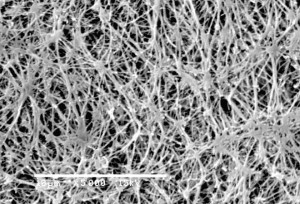

Sterlitech Corporation has expanded its line of laminated ePTFE filters with the addition of new Aspire™ membrane filters for microfiltration. With pore sizes ranging from 0.1 micron to 5.0 micron, the Aspire™ membranes broadens Sterlitech’s pore size selection to cover a wider range of applications. The new Aspire™ membranes also include hydrophilic and oleophobic filters. “The new Aspire laminated ePTFE membranes complement our existing laminated and unlaminated PTFE products,” states Mark Spatz, president of Sterlitech. “The hydrophilic and oleophobic membranes also introduce capabilities that our previous ePTFE products didn’t have.” Expanding PTFE creates a dense, web-like structure with billions of microscopic pores, which trap particulates

- Tuesday, April 01, 2014

To view this white paper in PDF form, click here. Also see Sterlitech's Schistosome Test Kit here. Schistosomiasis is a parasitic disease caused by Schistosome flatworms and is considered one of the Neglected Tropical Diseases, which are a group of tropical diseases endemic to low-income populations of Africa, Asia, and the Americas. However, Schistosomiasis affects more than 200 million people worldwide, and the CDC has placed it second only to malaria as the most devastating parasitic disease. Efforts to combat this infection are ramping up

![Join Sterlitech at BIO 2024 [Booth #5558]: Exploring the Future of Biotechnology](https://www.sterlitech.com/media/magefan_blog/b4.jpeg)